Product Description

Magtrol’s In-Line Torque Transducers provide extremely accurate torque and speed measurement over a very broad range. Each model has an integrated conditioning electronic module providing a ±5 VDC (±10 VDC) torque output and an open collector speed output. Magtrol Torque Transducers are very reliable, providing high overload protection, excellent long term stability and high noise immunity.

All transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits, most notably that no electronic components rotate during operation.

To provide customers with several price/performance options, Magtrol offers three torque transducer models: basic model (TMB Series), high accuracy (TM Series) and high speed with high accuracy (TMHS Series).

Each transducer consists of a hardened stainless steel shaft with smooth, splined or keyway shaft ends, an anodized aluminium housing containing the guide bearings and an electronic measurement conditioner.

The integrated electronic circuit, supplied by single DC voltage, provides torque and speed signals without any additional amplifier. The transducer is a stand-alone measuring chain. Connections are made by means of a 6-pole male connector mounted on the housing. A removable aluminium base (delivered as standard with TM Series and TMHS Series models, and as an option for TMB Series transducers) allows fixed mounting of the transducer.

Features

- Integrated Torque and Speed Conditioning

- Torque Range: 0.1 N·m … 10 kN·m (0.07 lb·ft … 7375 lb·ft)

- Accuracy: < 0.1%

- Overload Capacity: 200%

- Breaking limit: up to 400%

- High Speed Applications: up to 50 000 rpm

- Non-Contact (no slip rings)

- No Electronic Components in Rotation

- No Electrical Noise

- Single DC Power Supply: 20 … 32 VDC

- Immediate Speed Detection

- Adjustable Torque Signal Frequency Pass Band up to 5 kHz

- Built-in Test Function

- Stainless Steel Shaft

- EMC Susceptibility Conforms to European Standards

Specifications and Drawings

For detailed information regarding technical specifications and detailed dimensional drawings, please refer to the product datasheet. The downloadable files concern our standard models. Files for special models (e.g. other shaft ends) are available on request, please contact our sales department. For any specific use we recommend that you contact our sales department in order to find the solution best suited to your needs.

| Model Number | Nominal Rated Torque (N·m) | Nominal Rated Torque (lb·ft) | TMB Accuracy Class | TMB Max. Speed (rpm) | TM Accuracy Class | TM Max. Speed (rpm) | TMHS Accuracy Class | TMHS Max. Speed (rpm)* | TM/TMHS Downloads | TMB Downloads |

|---|

| 301 | 0.1 | 0.07 | N/A | N/A | 0.2% | 20 000 | N/A | N/A | pdf | step** | N/A |

| 302 | 0.2 | 0.15 | N/A | N/A | < 0.1% | 20 000 | N/A | N/A | pdf | step** | N/A |

| 303 | 0.5 | 0.37 | N/A | N/A | < 0.1% | 20 000 | < 0.1% | 40 000 | pdf | step** | pdf | step |

| 304 | 1 | 0.7 | < 0.1% | 6 000 | < 0.1% | 20 000 | < 0.1% | 50 000 | pdf | step** | pdf | step |

| 305 | 2 | 1.5 | < 0.1% | 6 000 | < 0.1% | 20 000 | < 0.1% | 50 000 | pdf| step** | pdf | step |

| 306 | 5 | 3.7 | < 0.1% | 6 000 | < 0.1% | 20 000 | < 0.1% | 50 000 | pdf | step** | pdf | step |

| 307 | 10 | 7.4 | < 0.1% | 6 000 | < 0.1% | 20 000 | < 0.1% | 50 000 | pdf | step** | pdf | step |

| 308 | 20 | 15 | < 0.1% | 6 000 | < 0.1% | 20 000 | < 0.1% | 50 000 | pdf | step** | pdf | step |

| 309 | 20 | 15 | < 0.1% | 4 000 | < 0.1% | 10 000 | < 0.1% | 32 000 | pdf | step | pdf | step |

| 310 | 50 | 37 | < 0.1% | 4 000 | < 0.1% | 10 000 | < 0.1% | 32 000 | pdf | step | pdf | step |

| 311 | 100 | 74 | < 0.1% | 4 000 | < 0.1% | 10 000 | < 0.1% | 32 000 | pdf | step | pdf | step |

| 312 | 200 | 148 | < 0.1% | 4 000 | < 0.1% | 10 000 | < 0.1% | 24 000 | pdf | step | pdf | step |

| 313 | 500 | 369 | < 0.1% | 4 000 | < 0.1% | 10 000 | < 0.1% | 24 000 | pdf | step | pdf | step |

| 314 | 1 000 | 738 | N/A | N/A | < 0.1% | 7 000 | < 0.1% | 16 000 | pdf | step | N/A |

| 315 | 2 000 | 1475 | N/A | N/A | < 0.1% | 7 000 | < 0.1% | 16 000 | pdf | step | N/A |

| 316 | 5 000 | 3687 | N/A | N/A | < 0.1% | 5 000 | < 0.1% | 12 000 | pdf | step | N/A |

| 317 | 10 000 | 7375 | N/A | N/A | < 0.15% | 5 000 | < 0.15% | 12 000 | pdf | step | N/A |

* Higher speed available in certain sizes, please contact our sales department.

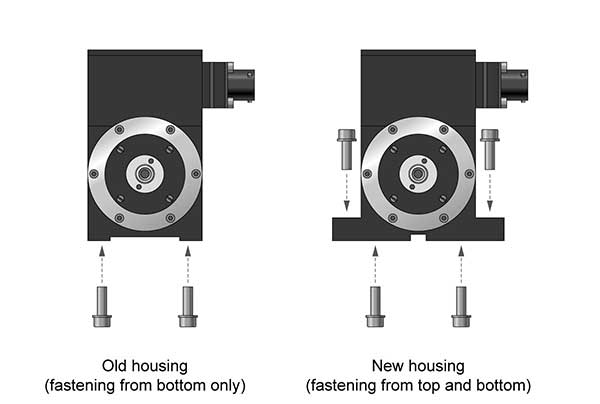

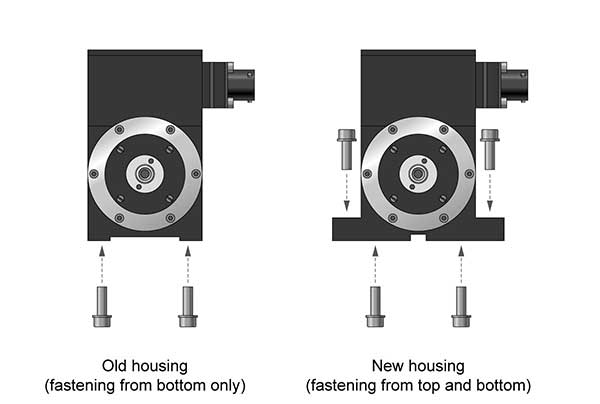

**This model is still available with narrow body (see illustration below). The old fastening system (fixation from the bottom only) is still available on request; please contact our sales department.

FIXATION FOR TM 301-308

MAGTROL has redesigned the mounting system for its small torque transducers (TM 301-308). The new mounting base allows not only installation of the torque transducers from below as before, but also installation from the top. It also integrates a centering key underneath its housing. The old fastening system (from below only) is still available as an alternative.

Operating Principles

The measuring system, based on the principle of a variable, torque proportional transformer coupling, consists of two concentric cylinders shrunk on the shaft on each side of the shaft’s deformation zone, and two concentric coils attached to the housing.

Both cylinders have a circularly disposed coinciding row of slots and rotate with the shaft inside the coils. An alternating current with the frequency of 20 kHz flows through the primary coil. When no torque is applied, the slots on the two cylinders fail to overlap. When torque is applied, the deformation zone undergoes an angular deformation and the slots begin to overlap.

Thus a torque-proportional voltage is on the secondary coil. The conditioning electronic circuit incorporated in the transducer converts the voltage to a nominal torque signal of 0 … ± 5 VDC. A low-pass filter (Butterworth / 2nd order), adjustable from 5 kHz … 1 Hz, allows tuning of the torque signal

frequency limitation.

An optical sensor reads the speed on a toothed pattern machined directly on the measuring system. The electronic conditioner outputs a frequency signal proportional to the shaft rotational speed. An active circuit compensates the zero and sensitivity temperature drifts within a tolerance of 0.1 % / 10 K.

Applications

TM, TMB and TMHS Series Torque Transducers provide dynamic torque and speed measurement of:

- Propellers – aerospace, marine and helicopter

- Windshield wipers, electrical windows, starters, generators and brakes in automobile industry

- Pumps – water and oil

- Reduction gears and gearboxes

- Clutches

- Motorized valves

- Drills, pneumatic tools and other machine tools