WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 8198

[1] => 1127

[2] => 940

[3] => 8090

[4] => 1132

)

[post__not_in] => Array

(

[0] => 8282

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 8198

[1] => 1127

[2] => 940

[3] => 8090

[4] => 1132

)

[post__not_in] => Array

(

[0] => 8282

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_posts.* FROM wp_posts WHERE 1=1 AND wp_posts.ID IN (8198,1127,940,8090,1132) AND wp_posts.post_type = 'product' AND (wp_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 1132

[post_author] => 1

[post_date] => 2017-04-07 17:09:08

[post_date_gmt] => 2017-04-07 17:09:08

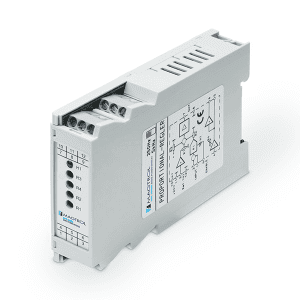

[post_content] => The BPM Series Current-Regulated Supply Module is widely used to supply and control the current (up to 3 A) of Magtrol Hysteresis Brakes and Clutches. This compact component is easy to mount (DIN-Rail snap-on) and recommended for easily controlling a wide range of brakes and clutches.

The analog input of the Current-Regulated Supply Module is designed for 0 -10 VDC signals. At the maximum set value of 10 VDC, the output current is adjustable from 0 to 100 %. With the use of adjustable potentiometers, the zero point can be shifted from 0 to 20 %.

[post_title] => BPM Series - Brake Power Module

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => bpm-series-brake-power-module

[to_ping] =>

[pinged] =>

[post_modified] => 2022-04-11 11:02:03

[post_modified_gmt] => 2022-04-11 15:02:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1132

[menu_order] => 105

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 8198

[post_author] => 2

[post_date] => 2019-05-16 15:10:57

[post_date_gmt] => 2019-05-16 19:10:57

[post_content] => Model 5251-2 is an open frame, 0-1A current regulated power supply for use with Magtrol hysteresis brakes and clutches. It has a high input impedance that allows for a variety of sensors and transducers to be used. It features a selectable 0-100 mV/0-5 VDC monitor out that allows connection to a PLC, voltmeter, display or other monitoring device. This allows the user to monitor the current applied directly to the brake or clutch, if desired. With regulated current, torque drift caused by temperature changes within the brake coil is eliminated. Braking control is enabled by using either a 10-turn potentiometer or by an external 0–5 VDC control signal.

Ordering Information

[table id=186 /]

[post_title] => 5251-2 - Current Regulated Power Supply

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => 5251-2-current-regulated-power-supply

[to_ping] =>

[pinged] =>

[post_modified] => 2022-04-11 11:00:49

[post_modified_gmt] => 2022-04-11 15:00:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=8198

[menu_order] => 103

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 8090

[post_author] => 2

[post_date] => 2019-04-18 09:57:15

[post_date_gmt] => 2019-04-18 13:57:15

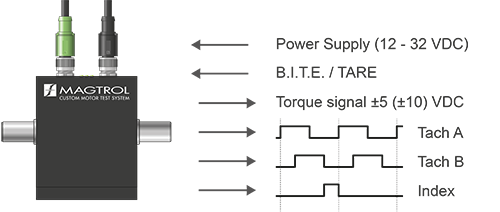

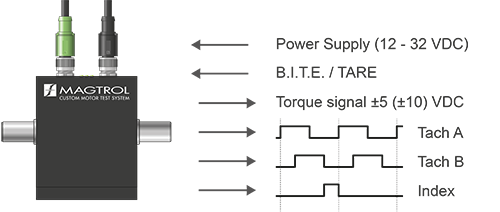

[post_content] => Magtrol’s TS 100 Series In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0 V DC to ± 5 V DC (±10 V DC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360 PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1 PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TS 100 Series sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights located on the sensor cover allow a visual check of the sensor status by color code (combination of the 3 LEDs). The sensor is powered by 24 V DC (12 - 32 V DC) through its 8-pole connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector. Available torque ranges from 0.02 N·m ... 500 N·m.

Features

- Integrated torque, speed and angle conditioning

- Torque range: from 0.02 N·m ... 500 N·m

- Integrated speed encoder with index

- Accuracy: < 0.1 % (0.05%)

- Overload capacity: 200 %

- Overload limit: 300 %

- Speed range: up to 15 000 rpm

- Torque output: ± 5 VDC (± 10 VDC)

- USB interface & analog connection

- LED operating status control

- Non-contact (no slip rings)

- Single DC power supply: 12 - 32 VDC

USB & Analog Output

The sensor offers both an isolated USB interface and an analog output. Both signals can be utilized simultaneously. For example, control loop data can be acquired using a computer via the USB interface while fast data acquisition can be performed using the analog output. In addition torque, speed, and angle data can be acquired using the USB interface while fast control loop data can be acquired using the analog output signals. The refresh time of the continuous analog signals is 100 μs (10 kHz). The analog signal provides a 0 to ± 5 VDC output corresponding to the sensor nominal range up to 200 % of measuring range (0 to ± 10 VDC). The USB interface can easily be connected and used with the LabVIEW™ dedicated software delivered with the sensor.

Integrated Encoder

TS 100 Series Torque Sensors integrate a high-end encoder with 360 PPR (Pulses Per Revolution) on 2 distinct signals (Tach A, Tach B) 90° out of phase providing an angular measurement resolution of ≤0.25°. A third signal offers 1 PPR (Z) providing an angular reference. The sensor body is marked with «Encoder Side» to indicate the encoder location. In low speed applications, where the angular position / accuracy of the test object is important, the encoder side needs to be directly connected to the test object so that the angular measurement is not influenced by the sensor deformation zone. Depending on sensor model, the number of pulses can be 360, 400 or 720 PPR (refer to specification table) and higher rate up to 5 000 PPR are available in option.

System Status Indicators

A color code is given by the activation of 3 LEDs lights (Yellow, Green, Red) located on the top cover of the sensor. This color code continuously communicates the operating status of the sensor, such as measuring status, tare functions, offset value, B.I.T.E. (Built-In Test Equipment) and overload.

Electrical Configuration

[caption id="attachment_8106" align="alignnone" width="500"]

TS 100 Series Torque Sensor electrical input and output[/caption]

Operating Principles

The measuring system is based on strain gauge technology directly applied on the sensor measuring section and connected in Wheatstone full bridge circuit. The strain gauge and its associated front end amplifier are powered by a high frequency power transfer. Under the applied torque, the measuring section will elastically deform providing a strain in the measuring elements. A microprocessor conditions the signal from the amplifier and transfers the measured values to the stator via contactless telemetry data transfer. On board micro-controllers manage all the internal functions, such as power transfer, data collecting and filtering, calibration and set-up, tare and B.I.T.E. (Build-In Test Equipment) functions, as well as the LED operating status control code. The sensor is supplied by 24 VDC (12 - 32 VDC) from the analog connector. The signal cutoff frequency can be digitally selected and configured in a range from 2 Hz up to 1 000 Hz.

[post_title] => TS 100 Series - Torque Sensors

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => ts-torque-sensors

[to_ping] =>

[pinged] =>

[post_modified] => 2023-08-10 11:21:10

[post_modified_gmt] => 2023-08-10 15:21:10

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=8090

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 940

[post_author] => 1

[post_date] => 2017-04-06 18:54:30

[post_date_gmt] => 2017-04-06 18:54:30

[post_content] => Magtrol’s In-Line Torque Transducers provide extremely accurate torque and speed measurement over a very broad range. Each model has an integrated conditioning electronic module providing a ±5 VDC (±10 VDC) torque output and an open collector speed output. Magtrol Torque Transducers are very reliable, providing high overload protection, excellent long term stability and high noise immunity.

All transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits, most notably that no electronic components rotate during operation.

To provide customers with several price/performance options, Magtrol offers three torque transducer models: basic model (TMB Series), high accuracy (TM Series) and high speed with high accuracy (TMHS Series).

Each transducer consists of a hardened stainless steel shaft with smooth, splined or keyway shaft ends, an anodized aluminium housing containing the guide bearings and an electronic measurement conditioner.

The integrated electronic circuit, supplied by single DC voltage, provides torque and speed signals without any additional amplifier. The transducer is a stand-alone measuring chain. Connections are made by means of a 6-pole male connector mounted on the housing. A removable aluminium base (delivered as standard with TM Series and TMHS Series models, and as an option for TMB Series transducers) allows fixed mounting of the transducer.

Features

- Integrated Torque and Speed Conditioning

- Torque Range: 0.1 N·m ... 10 kN·m (0.07 lb·ft ... 7375 lb·ft)

- Accuracy: < 0.1%

- Overload Capacity: 200%

- Breaking limit: up to 400%

- High Speed Applications: up to 50 000 rpm

- Non-Contact (no slip rings)

- No Electronic Components in Rotation

- No Electrical Noise

- Single DC Power Supply: 20 ... 32 VDC

- Immediate Speed Detection

- Adjustable Torque Signal Frequency Pass Band up to 5 kHz

- Built-in Test Function

- Stainless Steel Shaft

- EMC Susceptibility Conforms to European Standards

[post_title] => TM 300 Series - Torque Sensors

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => torque-transducers

[to_ping] =>

[pinged] =>

[post_modified] => 2023-08-09 15:04:41

[post_modified_gmt] => 2023-08-09 19:04:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=940

[menu_order] => 42

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 1132

[post_author] => 1

[post_date] => 2017-04-07 17:09:08

[post_date_gmt] => 2017-04-07 17:09:08

[post_content] => The BPM Series Current-Regulated Supply Module is widely used to supply and control the current (up to 3 A) of Magtrol Hysteresis Brakes and Clutches. This compact component is easy to mount (DIN-Rail snap-on) and recommended for easily controlling a wide range of brakes and clutches.

The analog input of the Current-Regulated Supply Module is designed for 0 -10 VDC signals. At the maximum set value of 10 VDC, the output current is adjustable from 0 to 100 %. With the use of adjustable potentiometers, the zero point can be shifted from 0 to 20 %.

[post_title] => BPM Series - Brake Power Module

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => bpm-series-brake-power-module

[to_ping] =>

[pinged] =>

[post_modified] => 2022-04-11 11:02:03

[post_modified_gmt] => 2022-04-11 15:02:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1132

[menu_order] => 105

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4f59c036777bb08cb87be96eb4d00a8d

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)