Description du produit

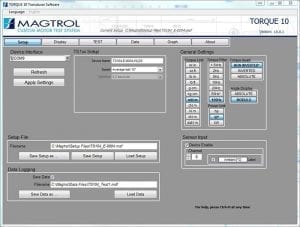

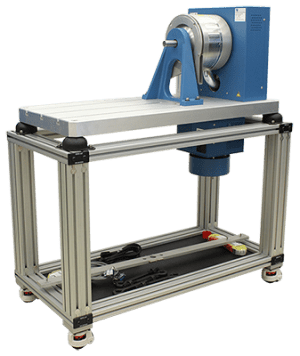

Magtrol’s DUAL TEST 7 is a state-of-the-art motor testing software for PC (Windows® XP sp3/7/8) based data acquisition. Used with a Magtrol Programmable Dynamometer Controller DSP7012, DUAL TEST 7 works on two channels independently with any Magtrol Dynamometer or In-Line Torque Transducer to help determine the performance characteristics of a motors under test. Up to 63 parameters are calculated and displayed utilizing DUAL TEST 7’s feature-rich testing and graphing capabilities.

An integral component of any Magtrol Motor Test System, DUAL TEST 7 performs curve tests in a manner best suited to the overall efficiency of the test rig. Written in LabVIEW™, DUAL TEST 7 has the flexibility to test a variety of motors in a multitude of configurations. The data generated from this user-friendly program can be stored, displayed and printed in tabular or graphical formats, and is easily imported into a spreadsheet.

Magtrol can also make custom modifications to the software to meet additional motor testing requirements.