WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 783

[1] => 16158

[2] => 410

[3] => 512

[4] => 507

)

[post__not_in] => Array

(

[0] => 16159

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 783

[1] => 16158

[2] => 410

[3] => 512

[4] => 507

)

[post__not_in] => Array

(

[0] => 16159

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_posts.* FROM wp_posts WHERE 1=1 AND wp_posts.ID IN (783,16158,410,512,507) AND wp_posts.post_type = 'product' AND (wp_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 16158

[post_author] => 2

[post_date] => 2024-11-01 13:50:52

[post_date_gmt] => 2024-11-01 17:50:52

[post_content] => The ATK-25 is a unique shaft alignment solution, specially designed for small equipment. The ATK can be used to measure parallel and angular alignment, for correction of pitch, yaw, vertical, and horizontal positioning. It works in crowded or constrained locations where other tools will not fit.

Alignment is critical for rotating equipment. Poor alignment can cause:

- Excessive Vibration: Misaligned shafts lead to higher vibrations, which can result in mechanical failure or decreased performance

- Increased Wear and Tear: Bearings, seals, and couplings can experience premature wear due to the

additional forces exerted by misaligned shafts

- Equipment Failure: Continuous operation with misaligned shafts can lead to mechanical failure,

resulting in costly repairs and downtime

- Reduced Quality: In many industries, precision machinery is critical to maintaining product quality

Proper alignment tools and techniques provide major benefits, and are essential to achieving:

- Smooth operation, with the lowest noise and highest performance

- Long lifespan of component parts and minimum maintenance costs

- Reliable Operation, with the minimum downtime

- High production quality

Motor testing also requires good shaft alignment to produce the most accurate and consistent results. Unfortunately, the shaft alignment solutions widely available are not designed for use with smaller equipment.

Held on the V-block of one shaft, the ATK measures two tangent points on the target shaft. From those two measurements, angle can be determined from rise-over-run. Parallel position can be determined by measuring the target shaft on two sides, 180° opposite.

The ATK-25 includes attachments to accommodate a range of axial spacings between shaft ends. It includes a high-quality depth indicator, and is supplied in a durable, fitted case with all necessary tools.

[post_title] => ATK-25 Alignment Tool Kit

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => atk-25-alignment-tool-kit

[to_ping] =>

[pinged] =>

[post_modified] => 2025-07-24 09:14:11

[post_modified_gmt] => 2025-07-24 13:14:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=16158

[menu_order] => 1

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). WB Series Dynamometers integrate a torque measuring system with accuracy ratings of ± 0.3 % to ± 0.5 % full scale, depending on size and system configuration.

Features

- 12 Models with Maximum Torque from 400 mN·m to 560 N·m (56.6 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed (≤ 80 000)

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 80 000 rpm (up to 100 000 rpm with

WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer is equipped with an optical speed sensor.

WB 32 is equipped with a 4 PPR (Pulses Per Revolution) encoder, WB 43 and WB 65 HS are equipped with a 30 PPR encoder; WB 65, WB 115 & WB 15 are equipped with a 60 PPR encoder.

[post_title] => WB Series - Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => eddy-current-dynamometers-wb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-30 15:47:19

[post_modified_gmt] => 2025-06-30 19:47:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=507

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 783

[post_author] => 1

[post_date] => 2017-04-05 18:46:23

[post_date_gmt] => 2017-04-05 18:46:23

[post_content] => Magtrol’s AMF Series Adjustable Motor Fixtures are used to secure small to medium-sized motors in place while running any test. These extremely versatile fixtures also enable easy motor centering for coupling to a Magtrol

HD Series Hysteresis Dynamometer. (Couplings can be supplied upon request.) Various motor lengths are accommodated by either an attached T-slotted base plate or sliding base, depending on the model.

The AMF-1, -2 and -3 Fixtures feature one or two adjustable bridges, each fitted with a fluted knob clamp screw, to allow clamping anywhere along the axis of the motor. The adjustable bridge on the AMF-V Fixture incorporates a straight-line action clamp with a V-angle rubber padded clamp to maximize the mounting area.

To safeguard the motor, locking thumb screws provide protection against vibration and all motor-to-fixture contact surfaces are nylon padded for scratch-free clamping.

[post_title] => AMF Series - Adjustable Motor Fixtures

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => amf-adjustable-motor-fixtures

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-27 11:47:41

[post_modified_gmt] => 2023-04-27 15:47:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=783

[menu_order] => 66

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => The Powder Brake Dynamometer (PB Series) contains, as its name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction. They are ideal for applications operating in the low to middle speed range or when operating in the middle to high torque range. Like

Hysteresis Brakes, Powder Brakes provide full torque at zero speed. Like the

Eddy-Current Brake Dynamometers, the PB series are water-cooled, allowing for power ratings up to 48 kW. The PB Dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale, depending on size and system configuration.

Features

- 9 Models with Maximum Torque from 5 N·m to 1 200 N·m (3.69 lb·ft to 885 lb·ft)

- Braking Power: 500 W to 48 kW

- Stable Braking Torque

- Low Moment of Inertia

- Operation in Either Rotational Direction

- Braking Torque Measurement Integrated

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The PB Series - Powder Dynamometers contain, as their name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction between rotor and stator. The Powder Dynamometers (PB) produce their rated torque at zero speed. The element to be tested can be loaded at standstill to determine the starting torque.

Optical Speed Sensor

Each PB Series Dynamometer has a standard optical speed sensor. PB 43 has an optical speed sensor with a 30 PPR (Pulses Per Revolution); PB 65, PB 115 & PB 15 has an optical speed sensor with a 60 PPR. For higher speed resolution in low speed applications, Magtrol offers a 600 PPR or 6 000 PPR encoder as an option.

[post_title] => PB Series - Powder Brake Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => powder-brake-dynamometers-pb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-03-31 13:22:57

[post_modified_gmt] => 2025-03-31 17:22:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=512

[menu_order] => 51

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 410

[post_author] => 1

[post_date] => 2017-04-05 12:20:44

[post_date_gmt] => 2017-04-05 12:20:44

[post_content] => Hysteresis Brake Dynamometers (HD Series) are versatile and ideal for testing in the low to medium power range (maximum 14 kW intermittent duty). With a Hysteresis Braking system, the Dynamometers do not require speed to create torque, and therefore can provide a full motor ramp from free-run to locked rotor. Brake cooling is provided by convection (no external source), by compressed air or by dedicated blower, depending on the model. All Magtrol Hysteresis Dynamometers have accuracy ratings of ± 0.25% full scale — depending on size and system configuration.

Features

- 16 Standard Models with Maximum Torque from 2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

- Hysteresis Braking System: Provides precise torque loading independent of shaft speed

- Motor Testing from No Load to Locked Rotor

- Accuracy: ±0.25% (Full Scale)

- Air Flow Sensor: For protection against overheating and operator error

- Standard Torque Units: English, Metric and SI

- Custom Dynamometers: for special torque and speed requirements

- Easy Calibration

The Hysteresis Braking System

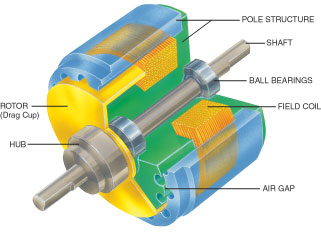

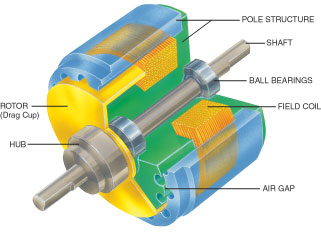

All Magtrol Hysteresis Dynamometers absorb power with a unique Hysteresis Braking System which provides frictionless torque loading independent of shaft speed. The Hysteresis Brake provides torque by the use of two basic components - a reticulated pole structure and a specialty steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from the field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 11:43:28

[post_modified_gmt] => 2025-06-05 15:43:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 5

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 16158

[post_author] => 2

[post_date] => 2024-11-01 13:50:52

[post_date_gmt] => 2024-11-01 17:50:52

[post_content] => The ATK-25 is a unique shaft alignment solution, specially designed for small equipment. The ATK can be used to measure parallel and angular alignment, for correction of pitch, yaw, vertical, and horizontal positioning. It works in crowded or constrained locations where other tools will not fit.

Alignment is critical for rotating equipment. Poor alignment can cause:

- Excessive Vibration: Misaligned shafts lead to higher vibrations, which can result in mechanical failure or decreased performance

- Increased Wear and Tear: Bearings, seals, and couplings can experience premature wear due to the

additional forces exerted by misaligned shafts

- Equipment Failure: Continuous operation with misaligned shafts can lead to mechanical failure,

resulting in costly repairs and downtime

- Reduced Quality: In many industries, precision machinery is critical to maintaining product quality

Proper alignment tools and techniques provide major benefits, and are essential to achieving:

- Smooth operation, with the lowest noise and highest performance

- Long lifespan of component parts and minimum maintenance costs

- Reliable Operation, with the minimum downtime

- High production quality

Motor testing also requires good shaft alignment to produce the most accurate and consistent results. Unfortunately, the shaft alignment solutions widely available are not designed for use with smaller equipment.

Held on the V-block of one shaft, the ATK measures two tangent points on the target shaft. From those two measurements, angle can be determined from rise-over-run. Parallel position can be determined by measuring the target shaft on two sides, 180° opposite.

The ATK-25 includes attachments to accommodate a range of axial spacings between shaft ends. It includes a high-quality depth indicator, and is supplied in a durable, fitted case with all necessary tools.

[post_title] => ATK-25 Alignment Tool Kit

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => atk-25-alignment-tool-kit

[to_ping] =>

[pinged] =>

[post_modified] => 2025-07-24 09:14:11

[post_modified_gmt] => 2025-07-24 13:14:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=16158

[menu_order] => 1

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 185cf6f62368d4a5d85b6cc11f071136

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 11:43:28

[post_modified_gmt] => 2025-06-05 15:43:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 5

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 16158

[post_author] => 2

[post_date] => 2024-11-01 13:50:52

[post_date_gmt] => 2024-11-01 17:50:52

[post_content] => The ATK-25 is a unique shaft alignment solution, specially designed for small equipment. The ATK can be used to measure parallel and angular alignment, for correction of pitch, yaw, vertical, and horizontal positioning. It works in crowded or constrained locations where other tools will not fit.

Alignment is critical for rotating equipment. Poor alignment can cause:

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 11:43:28

[post_modified_gmt] => 2025-06-05 15:43:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 5

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 16158

[post_author] => 2

[post_date] => 2024-11-01 13:50:52

[post_date_gmt] => 2024-11-01 17:50:52

[post_content] => The ATK-25 is a unique shaft alignment solution, specially designed for small equipment. The ATK can be used to measure parallel and angular alignment, for correction of pitch, yaw, vertical, and horizontal positioning. It works in crowded or constrained locations where other tools will not fit.

Alignment is critical for rotating equipment. Poor alignment can cause: