Product Description

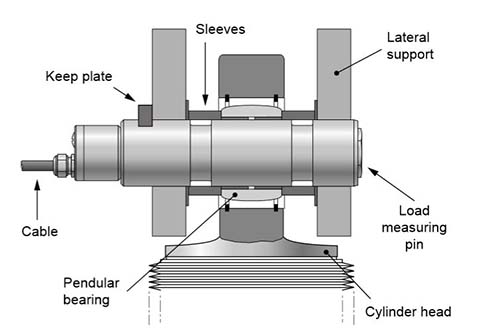

Magtrol’s AN Series Load Monitor, Signal Conditioner & Display are used for processing and displaying measurements from signals generated by transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges, such as Magtrol’s Load Measuring Pins LB Series(), Miniature Load Pins MB-02 Series() or any Custom Sensors based on strain gauge technology. The AN Series devices are suited for indoor use. These provides selectable input ranges and excitation voltages to accommodate cells of various types and sensitivities.

In some configurations (signal amplification, safety,…) it will be necessary to use the AN Series conditioner with a LMU Series – Load Monitoring Unit. If a remote or larger display is required a GAD Series – Digital Display (with heights ranging from 57 to 400 mm) can be used.

AN 1500 M: Load Monitor, Signal Conditioner & Display

As a Signal Conditioner, the AN 1500 M is designed to process and display signals coming from various types of transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges. As a Load Monitor the AN 1500 M can also receive any signal within the ± 150 mV DC range coming from a shunt, a converter or any type of transmitter.

The Load Monitor provides selectable input ranges (±15 mV, ±30 mV, ±150 mV) and excitation voltages (5 V, 10 V) to accommodate cells of various types and sensitivities. Two programming methods allow scaling of the meter to operate in the desired engineering units.

The basic instrument is a soldered assembly composed of a main board, a tri-color programmable display and a power circuit. Standard features include the reading of the input variable as well as remote (HOLD), the reading and memorization of minimum/maximum values (PEAK / VALLEY), TARE and RESET function, and a full complement of programmable logic functions.

AN 2000 C: Signal Conditioner & Display

The AN 2000 C Signal Conditioner & Display is designed to process and display signals coming from various types of transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges. It can also receive any signal within the range ± 300 mV DC coming from a shunt, a converter or any type of transmitter.

The Conditioner provides selectable input ranges (max. ±300 mV) and excitation voltages (5 V, 10 V) to accommodate cells of various types and sensitivities. Two programming methods allow scaling of the meter to operate in the desired engineering units.

The basic instrument consists of a PCB assembly including the main board, the display and the power supply filter, to which the A/D conversion circuit and the input option are added.

The functions of the basic instrument include the display of the input variable as well as the remote freezing of the display (HOLD), the reading of the stored minimum and maximum values (PEAK & VALLEY) and the TARE function with reset to zero.

Receive a quotation for a load pin according to your application's dimensions by filling out our

Receive a quotation for a load pin according to your application's dimensions by filling out our