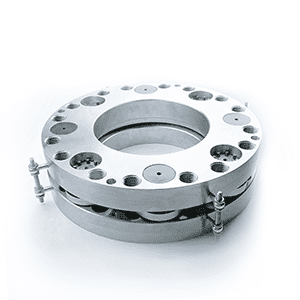

Product Description

With its compact, bearingless, maintenance-free design, the new TF 300 Series Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs.

Based on strain-gauge technology, the TF 300 Series Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup.

The contactless design of the Torque Flange Sensor permits a gap of up to 5 mm (typically 1 to 3 mm) between the rotor antenna and HF transmitter, which makes the signal acquisition insensitive to any axial or radial misalignment. Another advantage of this torque measurement system is its insusceptibility to signal interference—due to the fact that, unlike other designs, the antenna does not need to be looped around the sensor. Additionally, a protective cover can be mounted close to the sensor with no effect on the signal.

Specifications

For complete technical specifications, including detailed dimension drawings, download the data sheet.

Model Ratings

| Modela) | Rated Torque [N·m] | Overload Capacity (% of R.T.) | Accuracy Class | Maximum Speed [rpm] | Tortional Stiffness [kN·m/rad] | Deformation Angle [Degrees] | Sensor Weight [kg]c) | Moment of Inertia [kg·m²] | Moment of Inertia [lb·ft·s²] | Drawinge) |

|---|

TF 309 /

TFHS 309 | 20 | 200% | 0.1% | 17 000

20 000 | 50 | 0.023 | 1.4 | 0.0022 | 0.0016 | pdf | step |

TF 310 /

TFHS 310 | 50 | 200% | 0.1% | 17 000

20 000 | 72 | 0.04 | 1.5 | 0.0022 | 0.0017 | pdf | step |

TF 311 /

TFHS 311 | 100 | 200% | 0.1%b) | 17 000

20 000 | 86 | 0.067 | 1.5 | 0.0022 | 0.0017 | pdf | step |

TF 312 /

TFHS 312 | 200 | 200% | 0.1%b) | 17 000

20 000 | 106 | 0.108 | 1.5 | 0.0023 | 0.0017 | pdf | step |

TF 313 /

TFHS 313 | 500 | 200% | 0.1%b) | 15 000

20 000 | 850 | 0.034 | 1.9 | 0.0046 | 0.0034 | pdf | step |

TF 314 /

TFHS 314 | 1 000 | 200% | 0.1%b) | 15 000

20 000 | 1 285 | 0.045 | 2.0 | 0.0047 | 0.0035 | pdf | step |

TF 315 /

TFHS 315 | 2 000 | 200% | 0.1%b) | 10 000 | 2 476 | 0.04 | 5.2 | 0.0111 | 0.0082 | pdf | step |

TF 316 /

TFHS 316 | 5 000 | 200% | 0.1%b) | 10 000

12 000 | 5 573 | 0.051 | 5.0 | 0.0252 | 0.0186 | pdf | step |

TF 317 /

TFHS 317 | 10 000 | 150%d) | 0.1%b) | 10 000

12 000 | 6 141 | 0.093 | 6.0 | 0.0276 | 0.0204 | pdf | step |

| TF 318 | 20 000 | 200% | 0.1% – 0.2% | 3 500 | 44 000 | 0.026 | 56.0 | 1.3430 | 0.9911 | pdf | step |

| TF 319 | 50 000 | 180%d) | 0.1% – 0.2% | 3 500 | 74 700 | 0.038 | 59.0 | 1.3790 | 1.0177 | pdf | step |

| TF 320 | 100 000 | 180%d) | 0.1% – 0.2% | 3 500 | 1 047 000 | 0.055 | 63.5 | 1.3970 | 1.0310 | pdf | step |

a) Torque up to 150 kN·m or higher, and high speed versions are available on request

b) Linearity- hysteresis error 0.05 % is available on request

c) Add 0.8 – 2.8 kg to weight (depending on configuration), for electronic devices attached to the sensor (HF transmitter, receiver, speed conditioner,…)

d) Dynamic torque peak values are due to force transmission limit of mounting screws

e) The physical design of the HS version is identical to the standard version, only the specifications are different. If you want a specific sales drawing for the HS version, you can request it from our sales network

Ratings Common to All TF 300 Series Sensors

| Torque Measurement |

| Maximum Dynamic Torque without Damage (Overload Limit) | 400% of Rated Torque |

| Environment |

| Rated Temperature Range | +10 °C to +85 °C |

| Storage Temperature Range | -25 °C to +85 °C |

| Extended Temperature Range (optional) | -30 °C to +125 °C |

| Temperature influence on zero | 0.01 % / °C |

| Protection class | IP 42 (optional IP 54 and IP 65)a) |

| Electrical Characteristics |

| Power Supply | 24 V DC ±10%, max 350 mA

TF 318, TF 319 & TF 320: 100-240 VAC |

| Torque Output Signal (rated / max.) | ±5 V DC / ± 10 V DC |

| Filter Bandwidth | 0 to 1 kHZ (-3dB) / (optional 5 kHZ) |

| Speed Measurement (Option) |

| Number of Teeth | Depending on TF size; refer to number of teeth |

| Speed Pick-Up Transducer | Magnetoresistive |

| Minimum Speed Detection | < 1 rpm |

| Speed Output | TTL (pulses per revolution corresponds to number of teeth) |

a) With IP 54 & IP 65, the combined error for models TF 309 – TF 312 is degraded; it will be 0.15 % instead of 0.1 %.

Applications

TF 300 Series Torque Flange Sensors measure both static and dynamic torque on stationary and rotating shafts. They are used in general combustion engine, electric motor and gearbox test benches; and can also be mounted inline for active torque monitoring of transmissions, powertrains, wind generators, gas turbines, boat engines, etc.