Product Description

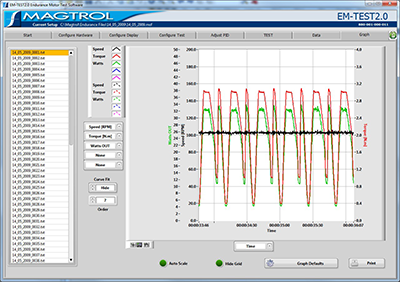

Magtrol’s EM-TEST is an Endurance Motor Testing Software for PC (Windows 7 SP1 / 10) based data acquisition. Combined with a Magtrol DSP 7000 Series High Speed Programmable Controller, EM-TEST works with any Magtrol dynamometer or in-line torque transducer to determine the performance characteristics of a motor under test. Up to 128 parameters are calculated and displayed utilizing EM-TEST’s unique testing and graphing capabilities.

An integral component of any Magtrol Endurance Motor Test System, EM-TEST performs curve testing in a manner best suited to the overall efficiency of the test rig. Written in LabVIEW™, EM-TEST has the flexibility to test a variety of motors in a multitude of configurations. The data generated from this user-friendly program can be stored, displayed and printed in tabular or graphical formats, and is easily imported into a spreadsheet.

Magtrol can also make custom modifications to the software to meet additional motor testing requirements.

Analog Input Measurement

Up to 128 Analog Sensors can be read and monitored during a motor test. Heat rise curves on the bearings, windings and housing of a motor can be performed and air flow/exhaust efficiencies can be measured with an air tool or internal combustion engine.

EM-TEST, with its complete dynamometer control, even allows for analog measurement while performing load simulation for duty cycle and life testing.

CAUTION: Specific hardware (e.g. NI™ 9211,…) is required to enable this function.

Temperature Sensor Measurement

Up to 128 thermocouples can be read and monitored during a motor test. Heat rise curves on the bearings, windings and housing of a motor can be performed. EM-TEST, with its complete dynamometer control, allows for sensor measurement while performing load simulation for duty cycle and life testing.

Hysteresis function: If the temperature exceeds the high threshold, the test passes to PAUSE mode and a relay is disabled. When the temperature passes under the low threshold, the test passes to RUN mode and a relay is enabled.

CAUTION: Specific hardware (e.g. NI™ 9211,…) is required to enable this function.

Relay Control

Up to 12 relays can be controlled during test. The state of each relay can be set for each step.

CAUTION: Specific hardware (e.g. NI™ 9482,…) is required to enable this function.