WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 410

[1] => 512

[2] => 507

[3] => 522

)

[post__not_in] => Array

(

[0] => 613

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 410

[1] => 512

[2] => 507

[3] => 522

)

[post__not_in] => Array

(

[0] => 613

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_posts.* FROM wp_posts WHERE 1=1 AND wp_posts.ID IN (410,512,507,522) AND wp_posts.post_type = 'product' AND (wp_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). The WB dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale (± 2% for WB 2.7), depending on size and system configuration. Additional options include: high-speed version, speed pickup, mechanical rotor blocking device, OEM version IS and vertical mounting.

Features

- 13 Models with Maximum Torque from 300 mN·m to 560 N·m (42 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 65 000 rpm (up to 100 000 rpm with WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer has an optical speed sensor delivered as standard. WB 2.7 & WB 43 has an optical speed sensor with a 30-PPR encoder; WB 65, WB 115 & WB 15 has an optical speed sensor with a 60-PPR encoder.

[post_title] => WB Series - Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => eddy-current-dynamometers-wb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:03:20

[post_modified_gmt] => 2023-04-13 19:03:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=507

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => The Powder Brake Dynamometer (PB Series) contains, as its name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction. They are ideal for applications operating in the low to middle speed range or when operating in the middle to high torque range. Like

Hysteresis Brakes, Powder Brakes provide full torque at zero speed. Like the

Eddy-Current Brake Dynamometers, the PB series are water-cooled, allowing for power ratings up to 48 kW. The PB Dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale (± 2% for PB 2.7), depending on size and system configuration. Additional mounting possibilities include speed pickup and OEM version IS.

Features

- 12 Models with Maximum Torque from 600 mN·m to 1 200 N·m (84 oz·in to 885 lb·ft)

- Braking Power: 150 W to 48 kW

- Stable Braking Torque

- Low Moment of Inertia

- Operation in Either Rotational Direction

- Braking Torque Measurement Integrated

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The PB Series - Powder Dynamometers contain, as their name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction between rotor and stator. The Powder Dynamometers (PB) produce their rated torque at zero speed. The element to be tested can be loaded at standstill to determine the starting torque.

Optical Speed Sensor

Each PB Series Dynamometer has an optical speed sensor delivered as standard. PB 2.7 & PB 43 has an optical speed sensor with a 30-PPR encoder; PB 65, PB 115 & PB 15 has an optical speed sensor with a 60-bits pulse wheel. For higher speed resolution in low speed applications, Magtrol offers a 600-PPR or 6000-PPR encoder as an option.

[post_title] => PB Series - Powder Brake Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => powder-brake-dynamometers-pb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:03:44

[post_modified_gmt] => 2023-04-13 19:03:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=512

[menu_order] => 47

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 522

[post_author] => 1

[post_date] => 2017-04-05 13:55:52

[post_date_gmt] => 2017-04-05 13:55:52

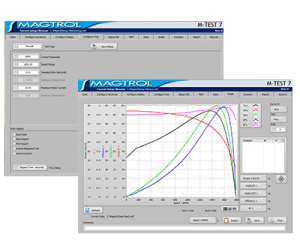

[post_content] => Magtrol's M-TEST 7 is a state-of-the-art motor testing program for PC (Windows® 10/11 64-bit) based data acquisition. Used with a Magtrol Programmable Dynamometer Controller, M-TEST 7 works with any Magtrol Dynamometer or In-Line Torque Transducer to help determine the performance characteristics of a motor under test. Up to 63 parameters are calculated and displayed utilizing M-TEST 7's feature-rich testing and graphing capabilities.

National Instruments LabVIEW an integral component of any Magtrol Motor Test System, M-TEST 7 performs ramp, curve, manual, pass/fail, coast, temperature, locked rotor temperature and running heating temperature tests in a manner best suited to the overall efficiency of the test rig. Written in LabVIEW™, M-TEST 7 has the flexibility to test a variety of motors in a multitude of configurations. The data generated from this user-friendly program can be stored, displayed and printed in tabular or graphical formats, and is easily imported into a spreadsheet.

Magtrol can also make custom modifications to the software to meet additional motor testing requirements.

NOTE: M-TEST 7 does not support the following:

- 5240, 4629B or older controllers

- 4612B, 4614B or older power analyzers

- National Instruments FieldPoint analog I/O

- Advantech PCL-725, PCI-1760 digital I/O

**MTEST-7 Motor Test Software is offered as a single seat license. Additional seats can be purchased and added to the original license. Contact sales for pricing.**

[table id=21 /]

License Verification via Crypkey Casper E-Register

Casper eRegister provides automatic authorization of M-TEST 7 using serial numbers. With this solution, the customer pre-pays the license fee and is then provided with a serial number to automatically obtain a code to unlock M-TEST 7 via the Internet. Casper eRegister works 24/7/365, without human intervention.

Just click on the electronic registration button on the M-TEST 7 license configuration screen.

Analog Input Measurement

Up to 128 thermocouples or analog sensors can be read and monitored during a motor test. Heat rise curves on the bearings, windings and housing of a motor can be performed and air flow/exhaust efficiencies can be measured with an air tool or internal combustion engine. M-TEST 7, with its complete dynamometer control, even allows for analog measurement while performing load simulation for duty cycle and life testing.

Applications

M-TEST 7—besides being well-suited for simulating loads, cycling the unit under test and motor ramping—is also ideal for production line and inspection applications, due to its pass/fail test function. Another time-saving feature that engineering labs will benefit from, is the ability to duplicate tests and run them automatically. This versatile program is extremely valuable to anyone involved in motor testing.

System Minimum Requirements

- Personal computer with Intel® Pentium® i5 processor (or equivalent)

- Microsoft® Windows® 10/11 64-bit

- 8 GB RAM

- 5 GB of available hard drive space

- VGA color monitor with minimum screen resolution of 1024 × 768

- National Instruments™ PCI-GPIB card, GPIB-USB-HS Interface(available from Magtrol). The GPIB card can be used for interfacing with Magtrol DSP6000, DSP6001 or DSP7000 Controllers.

- In addition, a USB Interface can be used with the DSP7000 or DSP7010 Controller.

M-TEST 7 Viewer

M-TEST 7 Viewer allows the user to create and modify test setups, and view, graph and compare data – everything standard M-TEST 7 does except perform tests. Free download, unlimited use.

Download M-TEST 7 Viewer

[post_title] => M-TEST 7 - Motor Testing Software

[post_excerpt] =>

Download free 30 day trial of M-TEST 7 Motor Testing Software.

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => m-test-7-motor-testing-software

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-27 16:05:23

[post_modified_gmt] => 2024-03-27 20:05:23

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=522

[menu_order] => 29

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 410

[post_author] => 1

[post_date] => 2017-04-05 12:20:44

[post_date_gmt] => 2017-04-05 12:20:44

[post_content] => Hysteresis Brake Dynamometers (HD Series) are versatile and ideal for testing in the low to medium power range (maximum 14 kW intermittent duty). With a Hysteresis Braking system, the Dynamometers do not require speed to create torque, and therefore can provide a full motor ramp from free-run to locked rotor. Brake cooling is provided by convection (no external source), by compressed air or by dedicated blower, depending on the model. All Magtrol Hysteresis Dynamometers have accuracy ratings of ± 0.25% full scale — depending on size and system configuration.

To better integrate dynamometers into systems, Magtrol offers both long and short base plates. The shorter base plate facilitates easier motor mounting when used with T-slot tables and Magtrol Adjustable Motor Fixtures, where as the long base plates are better suited for table top testing.

Features

- 16 Standard Models with Maximum Torque from 2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

- Hysteresis Braking System: Provides precise torque loading independent of shaft speed

- Motor Testing from No Load to Locked Rotor

- Accuracy: ±0.25% (Full Scale)

- Air Flow Sensor: For protection against overheating and operator error

- Standard Torque Units: English, Metric and SI

- Base Plate: Available in long or short versions

- Custom Dynamometers: for special torque and speed requirements

- Easy Calibration

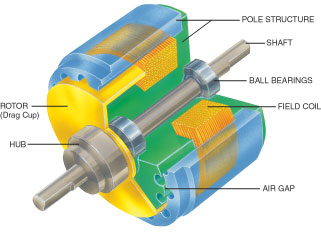

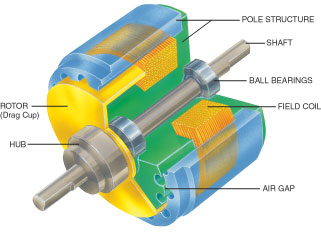

The Hysteresis Braking System

All Magtrol Hysteresis Dynamometers absorb power with a unique Hysteresis Braking System which provides frictionless torque loading independent of shaft speed. The Hysteresis Brake provides torque by the use of two basic components - a reticulated pole structure and a specialty steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from the field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:01:40

[post_modified_gmt] => 2023-04-13 19:01:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 43

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). The WB dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale (± 2% for WB 2.7), depending on size and system configuration. Additional options include: high-speed version, speed pickup, mechanical rotor blocking device, OEM version IS and vertical mounting.

Features

- 13 Models with Maximum Torque from 300 mN·m to 560 N·m (42 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 65 000 rpm (up to 100 000 rpm with WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer has an optical speed sensor delivered as standard. WB 2.7 & WB 43 has an optical speed sensor with a 30-PPR encoder; WB 65, WB 115 & WB 15 has an optical speed sensor with a 60-PPR encoder.

[post_title] => WB Series - Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => eddy-current-dynamometers-wb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:03:20

[post_modified_gmt] => 2023-04-13 19:03:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=507

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 06e11953acafb82c59fd626960039c7c

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:01:40

[post_modified_gmt] => 2023-04-13 19:01:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 43

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). The WB dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale (± 2% for WB 2.7), depending on size and system configuration. Additional options include: high-speed version, speed pickup, mechanical rotor blocking device, OEM version IS and vertical mounting.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-13 15:01:40

[post_modified_gmt] => 2023-04-13 19:01:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 43

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). The WB dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale (± 2% for WB 2.7), depending on size and system configuration. Additional options include: high-speed version, speed pickup, mechanical rotor blocking device, OEM version IS and vertical mounting.