Produktbeschreibung

Die Steuereinheit DSP 7010 Series von Magtrol ist ein Dynamometer-Controller mit fortschrittlicher digitaler Signalverarbeitungstechnologie (Digital Signal Processing). Er bietet erweiterte Messfunktionen für die Prüfung von Elektromotoren.

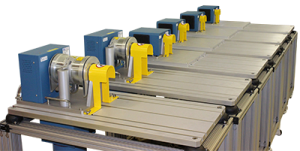

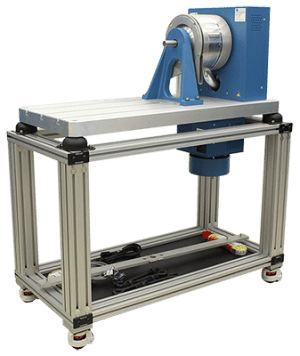

Der Controller ist mit allen Magtrol-Dynamometern kompatibel, unabhängig davon, ob es sich um Hysterese- (HD Serie), Wirbelstrom- (WB Serie) oder Magnetpulver-(PB-Serie) Leistungbremsen handelt. Er kann auch mit Drehmomentsensoren (TS-, TM-, TF-Serie) für ein Messsystem mit geregelte Systeme oder anderen Zusatzgeräten kombiniert werden. Der DSP 7010 ermöglicht in Verbindung mit der Magtrol-Software eine vollständige Steuerung über USB- oder GPIB-Schnittstellen. Seine Frontschnittstelle macht die Bedienung einfach und intuitiv.