Product Description

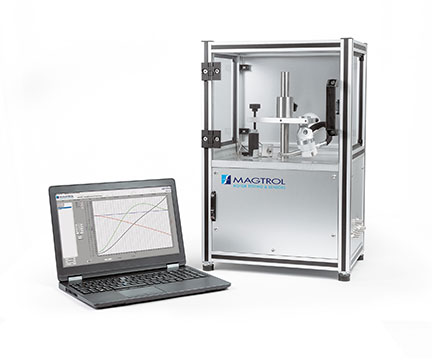

The MSD – Mega Speed Dynamometer was developed for the testing of very high speed motors such as BLDC, Dental Handpieces, Air Turbines and Surgical Tools. The braking effect is based on Eddy-Current induced on an aluminum disc directly mounted on the DUT (Device Under Test) shaft.

Torque is measured frictionless by a Reaction Torque Sensor mounted under the test bench surface. Due to the thermal effect on the disc, the Mega Speed Dynamometer is not suitable for endurance testing, but can be used to generate a fast curve or perform point to point testing. An infrared sensor monitors the temperature of the disc and stops the test in case of overheating. The disc can be designed and sized according to the motor parameters.

The system is contactless therefore alignment is not critical. Due to this, the system has very low inertia and therefore no residual or drag torque thus having less influence on testing parameters. The speed limitation is based on the Motor Under Test and its ability to drive the disc. Systems reaching speeds over 380 000 rpm have already been manufactured.

MSD-TEST Software is developed in a LabVIEW™ environment. It controls the system and captures the test data. It allows the programing set up of a dedicated test profile.

Every Mega Speed Dynamometer will be adapted around the motor characteristics and performances to match the best possible test results. Specific motor fixtures will be designed to suit each motor form and dimensions. Motor fixtures are available for fixturing handpiece or motor.

Air pressure sensor(s) can be provided as an option. The systems offers 2 analog ±10 VDC outputs as well as 6 analog ±10 VDC inputs (which can be configured for speed, torque, pressure,…) Included calibration weights and arms allow to conduct periodical calibration process supported by a dedicated software routine.

The Mega Speed Dynamometer (MSD System) allows the testing of Dentistry – Handpieces and Motors according to ISO 14457. It enhances Magtrol’s expertise in high-speed applications and ideally complements the WB 23 & WB 27 Dynamometers, enabling motor testing up to 100 000 rpm, with nominal torque of 80 mN·m, 150 mN·m respectively.

Configuration

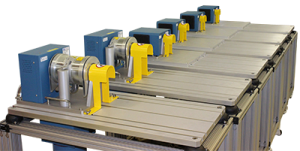

The test system, its computer program and especially its mounting system are customizable according to the devices to be tested. The fixture system is designed for two standard configurations. The first version consists of a fixture for high speed micro-motors and the second version consists of a special fixture for testing handpieces.

Electrical Micro-Motors Configuration

Handpiece configuration

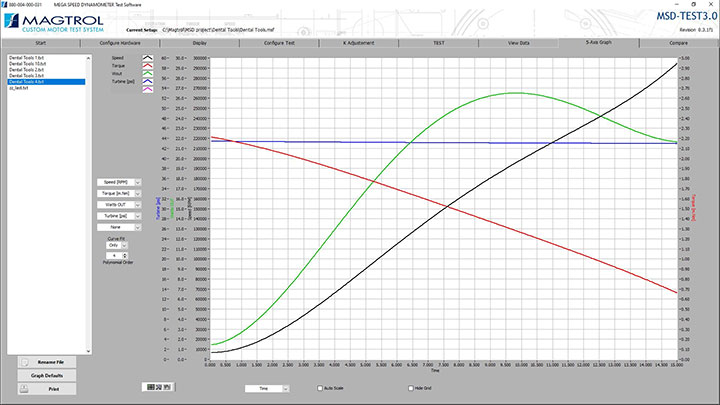

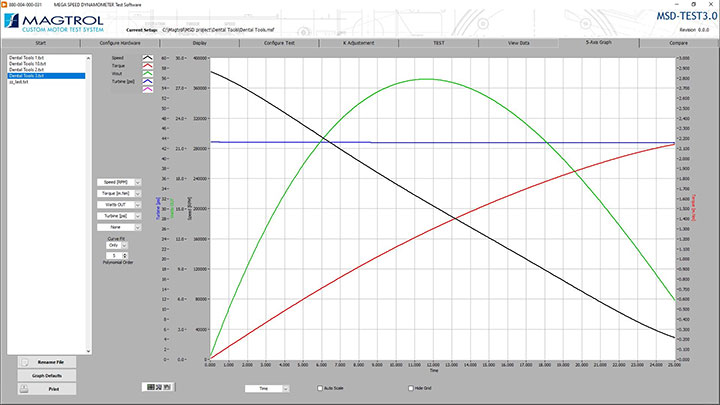

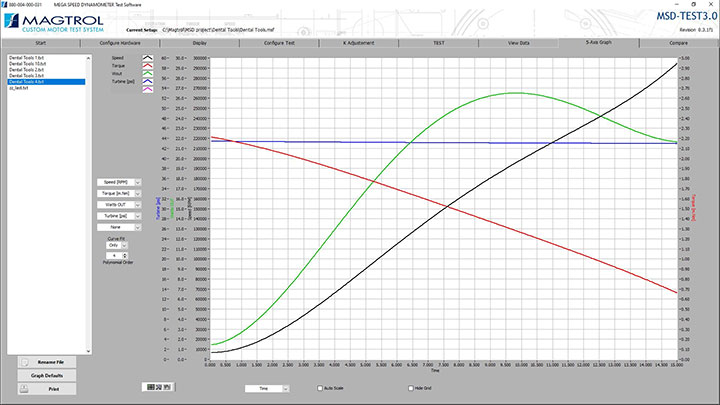

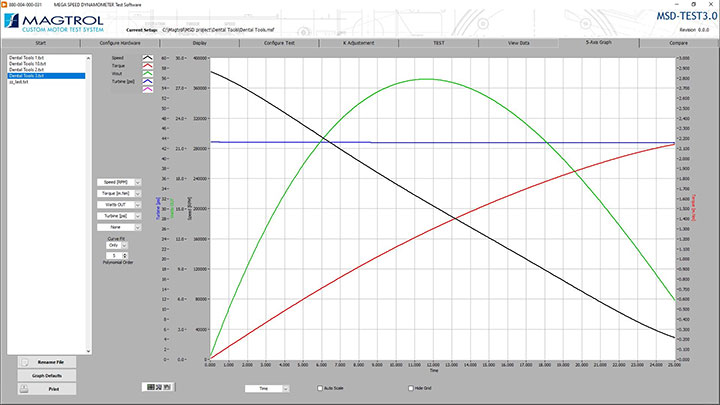

Curves

The MSD-TEST Software (included) allows the configuration of the system as well as the programing of the test sequences and set-up. It displays test curves and data during testing while recording all measured values as data table and txt files. Parameters can be displayed in graphic form (up to 5 axes simultaneously). It is also easy to print or export the data as a Microsoft® Excel spreadsheet.

Test curves (RAMP UP) of a Dental Turbine conducted on MSD – Mega Speed Dynamometer with Speed: ≤ 280 000 rpm and Torque: 0.7 … 2.18 mN·m.

Test curves (RAMP DOWN) of a Dental Turbine conducted on Mega Speed Dynamometer with Speed: ≤ 380 000 rpm and Torque: 0.7 … 2.18 mN·m.

Software

Magtrol MSD-TEST is an advanced motor testing software (Windows® based) for data acquisition and system control. Used with the Magtrol Mega Speed Dynamometer, the MSD-TEST determine the performance parameters of a motor / turbine under test. Mechanical properties (torque, speed, power), electrical properties (current, voltage, power) via power measurement system (optional), air pressure (optional) or temperature (optional) can be acquired. The software allow to configure the 2 analog ±10 V outputs as well as the 6 analog ±10 V inputs as needed. Test Set-up can be programmed and recalled any time.The system displays graphs of the tested object’s performances.

Magtrol MSD-TEST is an advanced motor testing software (Windows® based) for data acquisition and system control. Used with the Magtrol Mega Speed Dynamometer, the MSD-TEST determine the performance parameters of a motor / turbine under test. Mechanical properties (torque, speed, power), electrical properties (current, voltage, power) via power measurement system (optional), air pressure (optional) or temperature (optional) can be acquired. The software allow to configure the 2 analog ±10 V outputs as well as the 6 analog ±10 V inputs as needed. Test Set-up can be programmed and recalled any time.The system displays graphs of the tested object’s performances.

Developed in LabVIEW™, MSD-TEST has the flexibility to test a variety of rotating systems in a multitude of configurations. The data generated from this user-friendly program can be stored, displayed and printed in tabular or graphical formats, and is easily imported into a spreadsheet for further analyses. The software integrates a calibration routine, allowing the control and periodical calibration of the MSD Mega Speed Dynamometer.

Magtrol can also make custom modifications to the software to meet additional motor testing requirements.