Product Description

Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). WB Series Dynamometers integrate a torque measuring system with accuracy ratings of ± 0.3 % to ± 0.5 % full scale, depending on size and system configuration.

Features

- 12 Models with Maximum Torque from 400 mN·m to 560 N·m (56.6 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed (≤ 80 000)

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 80 000 rpm (up to 100 000 rpm with WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer is equipped with an optical speed sensor. WB 32 is equipped with a 4 PPR (Pulses Per Revolution) encoder, WB 43 and WB 65 HS are equipped with a 30 PPR encoder; WB 65, WB 115 & WB 15 are equipped with a 60 PPR encoder.

Specifications

| MODEL |

RATED TORQUE (METRIC)

[N·m] |

RATED TORQUE (ENGLISH)

[oz·in] |

RATED POWER

[kW] |

RATED SPEED

[rpm] |

MAX. SPEED

STANDARD

[rpm] |

MAX. SPEED

HIGH SPEED

(HS version)

[rpm] |

Downloads

(standard version) |

| 1 WB 32 |

0.4 |

56.6 |

0.5 |

11 950 |

80 000 |

N/A |

pdf | step |

| 2 WB 32 |

0.8 |

113.3 |

1.0 |

11 950 |

80 000 |

N/A |

pdf | step |

| 1 WB 43 |

1.5 |

211.2 |

1.5 |

9 550 |

50 000 |

65 000 |

pdf | step |

| 2 WB 43 |

3.0 |

422.4 |

3.0 |

9 550 |

50 000 |

65 000 |

pdf | step |

| MODEL |

RATED TORQUE (METRIC)

[N·m] |

RATED TORQUE (ENGLISH)

[lb·ft] |

RATED POWER

[kW] |

RATED SPEED

[rpm] |

MAX. SPEED

STANDARD

[rpm] |

MAX. SPEED

HIGH SPEED

(HS version)

[rpm] |

Downloads 1)

(standard version) |

| 1 WB 65 |

10 |

7.3 |

6 |

5 730 |

30 000 |

50 000 |

pdf | step |

| 2 WB 65 |

20 |

14.7 |

12 |

5 730 |

30 000 |

50 000 |

pdf | step |

| 1 WB 115 |

50 |

36.8 |

15 |

2 865 |

18 000 |

22 000 |

pdf | step |

| 2 WB 115 |

100 |

73.7 |

30 |

2 865 |

18 000 |

22 000 |

pdf | step |

| 1 WB 15 |

140 |

103.0 |

35 |

2 390 |

7 500 |

10 000 |

pdf | step |

| 2 WB 15 |

280 |

206.0 |

70 |

2 390 |

7 500 |

10 000 |

pdf | step |

| 3 WB 15 |

420 |

309.0 |

105 |

2 390 |

7 500 |

10 000 |

pdf | step |

| 4 WB 15 |

560 |

413.0 |

140 |

2 390 |

7 500 |

10 000 |

pdf | step |

1) Dimensions for the specific versions (HS, IS, …) can slightly vary from the standard versions. For specific drawing, please, contact our sales technicians.

Applications

Mounted on test benches, the WB Series Eddy-Current Dynamometers allow performance and reliability testing on driving elements such as servomotors, micromotors for cameras, fans, drills, combustion engine, pumps, pneumatic equipment, hydraulic transmission systems, gas turbines, spindles, compressors and motors for domestic appliances.

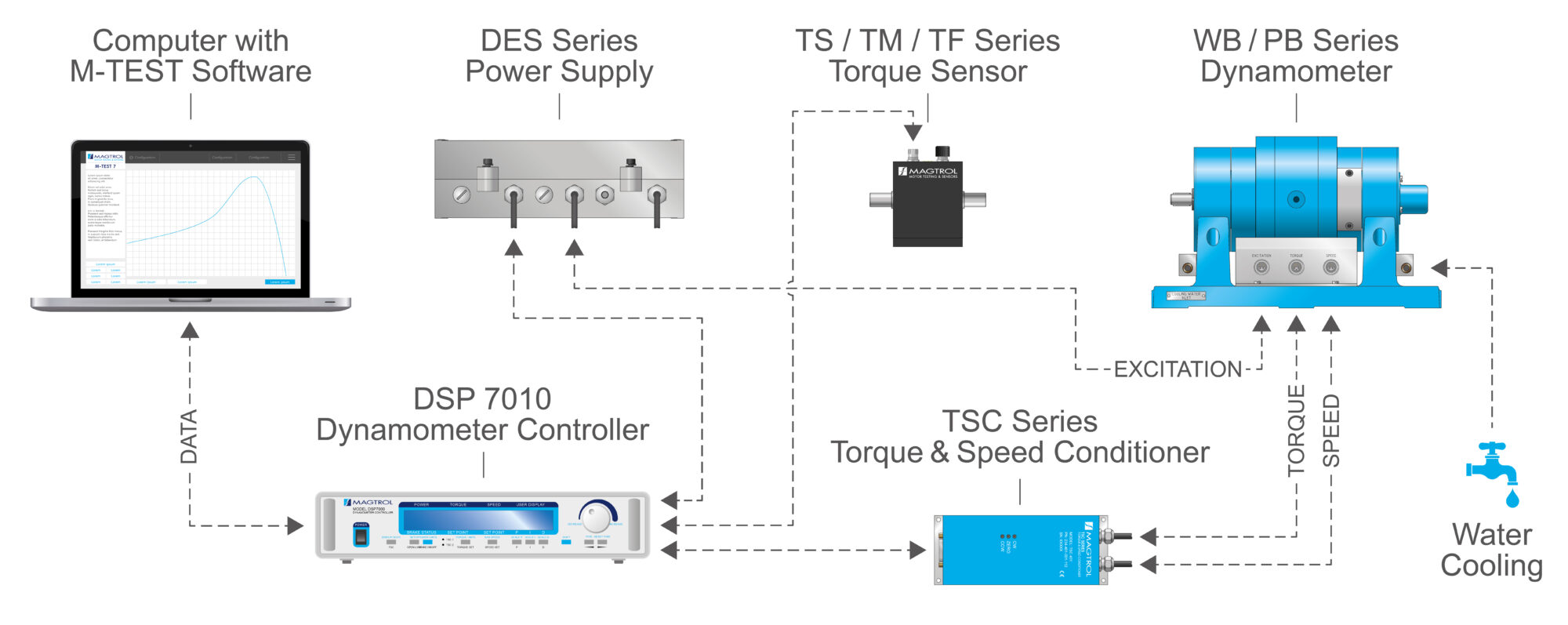

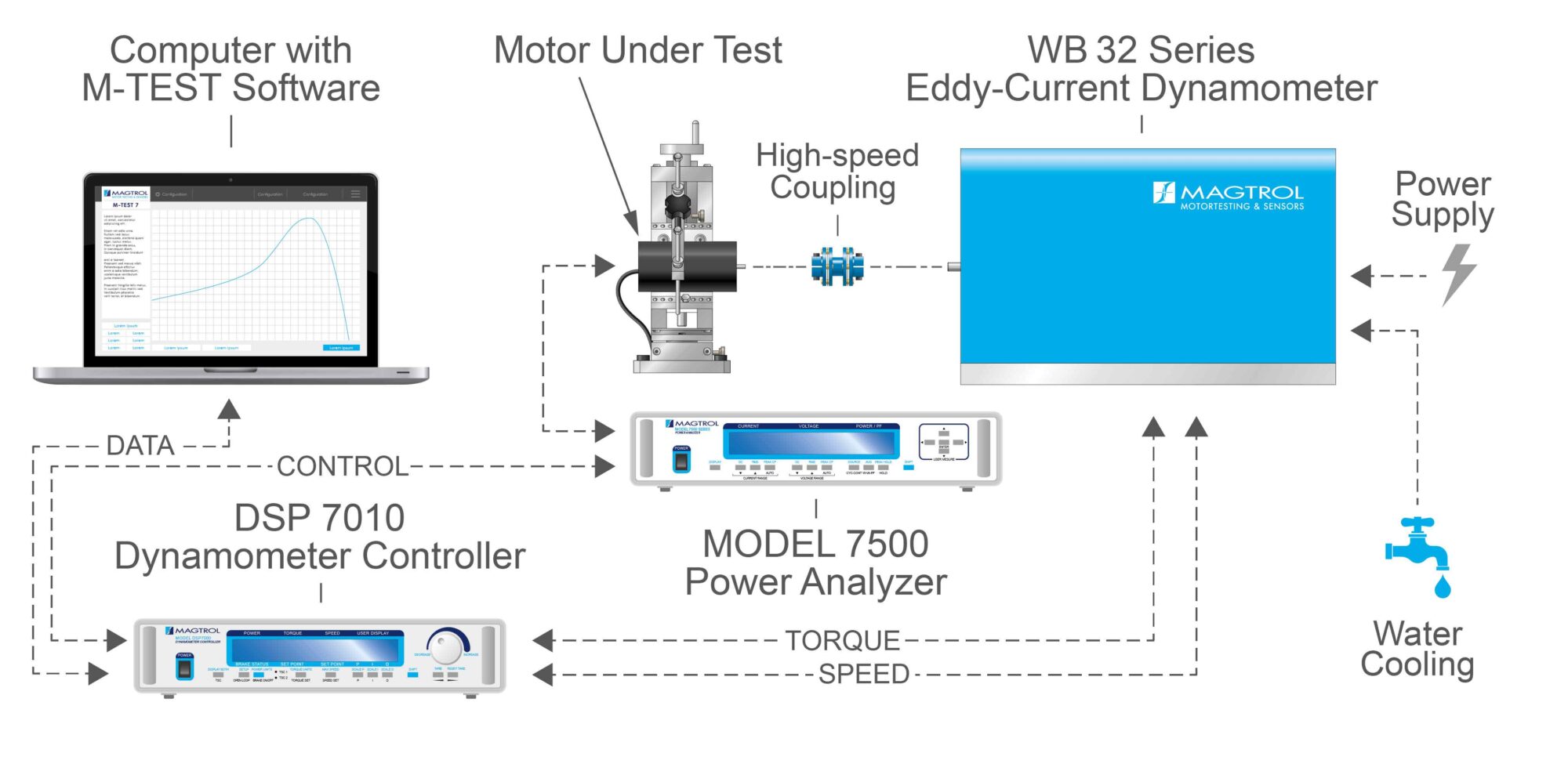

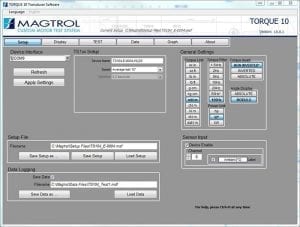

System Options

To help you select the components for your motor testing system, this table shows which (currently available) electronics and software support Magtrol’s different types of dynamometers.

| Model |

Description |

Hysteresis Dynamometers (including ED Series) |

Eddy-current Dynamometers |

Powder Brake Dynamometers |

Dial Weight Dynamometers |

| DYNAMOMETER CONTROLLERS |

| DSP7010 |

High-Speed Programmable Dynamometer Controller |

• |

• |

• |

|

| DSP7000 |

High-Speed Programmable Dynamometer Controller |

• |

• |

• |

|

| OTHER ELECTRONICS |

| TSC Series |

Torque/Speed Conditioner |

|

|

|

|

| 5500 |

Dynamometer Switch Box |

• |

|

|

|

| 5501 |

Dynamometer Switch Box |

|

• |

• |

|

| 5502 |

Dynamometer Switch Box |

• |

|

|

|

| 5503 |

Dynamometer Switch Box |

|

• |

• |

|

| SOFTWARE |

| M-TEST 7 |

Motor Testing Software |

• |

• |

• |

|

| POWER SUPPLIES |

| DES Series |

Power Supply |

|

• |

• |

|

| 5241 |

Power Amplifier |

Required for HD-825 Only |

|

|

|

| 5242 |

Power Amplifier |

Required for HD-825 Only |

|

|

|

| 5200 |

Power Supply |

|

|

|

• |

| 5210 |

Current-Regulated Power Supply |

|

|

|

• |

| 5250 |

Current-Regulated Power Supply |

|

|

|

• |

| ACCESSORIES |

| TAB |

Dynamometer Tables |

• |

• |

• |

• |

| AMF |

Adjustable Motor Fixtures |

• |

|

|

|

| FMF |

Fixed Motor Fixtures |

• |

|

|

|

| PT |

T-Slot Base Plate |

• |

• |

• |

|

| FRS |

Free-Run Speed Sensor |

• |

• |

• |

|

| SBB14 |

Signal Breakout Box |

• |

• |

• |

|

| SBB15 |

Signal Breakout Box |

• |

• |

• |

|

Dynamometer Selection

Magtrol Dynamometers cover a wide range of Torque, Speed and Mechanical Power ratings. To select the appropriate size Dynamometer for your motor testing needs, you will need to determine the Maximum Torque, Speed and Power applied to the Dynamometer:

Maximum Torque

It is important to consider all torque points that are to be tested, not only rated torque, but also Locked Rotor and Breakdown Torque. Dynamometer selection should initially be based on the maximum torque requirement, subject to determining the maximum power requirements.

Maximum Speed

This rating is to be considered independent of torque and power requirements, and is the maximum speed at which the Dynamometer can be safely run under free run or lightly loaded conditions. It is not to be considered as the maximum speed at which full braking torque can be applied.

Maximum Power Ratings

These ratings represent the maximum capability of the Dynamometer Braking System to absorb and dissipate heat generated when applying a braking load to the motor under test. The power absorbed and the heat generated by the Dynamometer is a function of the Torque (T) applied to the motor under test, and the resulting speed (n) of the motor. This is expressed in these power (P) formulas:

| SI: |

P (watts) |

= |

T (N·m) |

x |

n (rpm) |

x |

(1.047 × 10-1) |

| English: |

P (watts) |

= |

T (lb·in) |

x |

n (rpm) |

x |

(1.183 × 10-2) |

| Metric: |

P (watts) |

= |

T (kg·cm) |

x |

n (rpm) |

x |

(1.027 × 10-2) |

All of Magtrol's controllers, readouts and software calculate horsepower

as defined by 1 hp = 550 lb·ft / s. Using this definition: |

|

hp |

= |

P (watts) |

/ |

745.7 |

| To calculate power, use Magtrol's online motor power calculator |

The Dynamometer’s ability to dissipate heat is a function of how long a load will be applied. For this reason, the Maximum Power ratings given are based on continuous operation under load, as well as a maximum of 5 minutes under load.

To safely dissipate heat and avoid Dynamometer failure, the maximum power rating

is the most important consideration in selecting a Dynamometer.