Produktbeschreibung

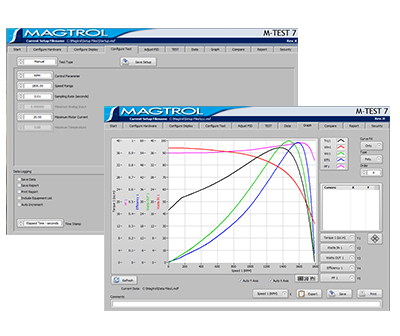

Die neue M-TEST 7 von Magtrol ist eine auf den neusten Stand der Technik gebrachte Motorenprüfsoftware und ist für den Einsatz mit einem Datenerfassungs-PC mit Windows®-Betriebssystem bestimmt. Zusammen mit einem Magtrol programmierbaren Leistungsbremsencontroller erlaubt die M-TEST 7-Software die Leistungseigenschaften eines getesteten Motors zu ermitteln. Bis zu 63 Parameter können dank der testfunktionsreichen und graphischen Fähigkeiten von M-TEST 7 kalkuliert und angegeben werden. Die mit LABVIEW™ entwickelte M-TEST 7 hat die Flexibilität eine breite Auswahl von Motoren in einer Vielzahl von Konfigurationen zu testen. Die von dieser bedienungsfreundlichen Software erfassten Messdaten können gespeichert, in tabellarischer oder graphischer Form angezeigt und gedruckt, oder leicht in ein Tabellenrechenprogramm exportiert werden. Magtrol ist ebenfalls in der Lage, kundenspezifische Änderungen zur Software zu machen, um sich an zusätzlichen Motorenprüfanforderungen anzupassen.

Merke:M-TEST 7 bietet fuer folgende Geräte keine Unterstuetzung::

- 5240, 4629B oder alte Controller

- 4612B, 4614B oder alte Poweranalyzers

- National Instruments FieldPoint analog I/O

- Advantech PCL-725, PCI-1760 digital I/O

MTEST-7 Motor Test Software wird als einzelnes angeboten Platz-Lizenz. Zusätzliche Plätze können gekauft und hinzugefügt, um die Original-Lizenz. Kontakt Vertrieb für die Preisfindung.

| Current Release | Release Date |

|---|---|

| Rev. ab | 07/23 |

License Verification via Crypkey Casper E-Register

Casper eRegister provides automatic authorization of M-TEST 7 using serial numbers. With this solution, the customer pre-pays the license fee and is then provided with a serial number to automatically obtain a code to unlock M-TEST 7 via the Internet. Casper eRegister works 24/7/365, without human intervention.

Just click on the electronic registration button on the M-TEST 7 license configuration screen.

Analog Input Measurement

Up to 128 thermocouples or analog sensors can be read and monitored during a motor test. Heat rise curves on the bearings, windings and housing of a motor can be performed and air flow/exhaust efficiencies can be measured with an air tool or internal combustion engine. M-TEST 7, with its complete dynamometer control, even allows for analog measurement while performing load simulation for duty cycle and life testing.

Applications

M-TEST 7—besides being well-suited for simulating loads, cycling the unit under test and motor ramping—is also ideal for production line and inspection applications, due to its pass/fail test function. Another time-saving feature that engineering labs will benefit from, is the ability to duplicate tests and run them automatically. This versatile program is extremely valuable to anyone involved in motor testing.

System Minimum Requirements

- Personal computer with Intel® Pentium® i5 processor (or equivalent)

- Microsoft® Windows® 10/11 64-bit

- 8 GB RAM

- 5 GB of available hard drive space

- VGA color monitor with minimum screen resolution of 1024 × 768

- National Instruments™ PCI-GPIB card, GPIB-USB-HS Interface(available from Magtrol). The GPIB card can be used for interfacing with Magtrol DSP6000, DSP6001 or DSP7000 Controllers.

- In addition, a USB Interface can be used with the DSP7000 or DSP7010 Controller.

M-TEST 7 Viewer

M-TEST 7 Viewer allows the user to create and modify test setups, and view, graph and compare data – everything standard M-TEST 7 does except perform tests. Free download, unlimited use.

[post_title] => HD Series - Hysterese-Leistungsbremsen

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 15:49:54

[post_modified_gmt] => 2023-04-21 13:49:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 26

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => Magnetpulverbremsen (PB Reihe) sind ideal für Anwendungen, die im niedrigen bis mittleren Drehzahlbereich oder bei Betrieb im mittleren bis hohen Drehmomentbereich arbeiten. Pulverbremsen liefern das volle Drehmoment bei Nulldrehzahl und sind wassergekühlt, wodurch Leistungen bis zu 48 kW möglich sind. Magnetpulverbremsen verfügen über eine Genauigkeit von ± 0.3 % bis ± 0.5 % vom Skalenendwert, abhängig vom Typ und dessen Konfiguration.

[post_title] => HD Series - Hysterese-Leistungsbremsen

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 15:49:54

[post_modified_gmt] => 2023-04-21 13:49:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 26

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => Magnetpulverbremsen (PB Reihe) sind ideal für Anwendungen, die im niedrigen bis mittleren Drehzahlbereich oder bei Betrieb im mittleren bis hohen Drehmomentbereich arbeiten. Pulverbremsen liefern das volle Drehmoment bei Nulldrehzahl und sind wassergekühlt, wodurch Leistungen bis zu 48 kW möglich sind. Magnetpulverbremsen verfügen über eine Genauigkeit von ± 0.3 % bis ± 0.5 % vom Skalenendwert, abhängig vom Typ und dessen Konfiguration.