Produktbeschreibung

Die Lastmessbolzen von Magtrol können sowohl einzeln als auch als Bestandteil eines kompletten Messsystems eingesetzt werden. Aufnehmer verschiedenster Ausführungen und Genauigkeitsklassen stellen in Verbindung mit unseren LMU-Lastmessverstärkern eine ideale und sichere Lösung zur Erfassung von Last, Kraft, Gewicht und zur Vermeidung von Überlast und Überbeanspruchungen in Systemen dar.

Die Lastmessbolzen von MAGTROL werden sowohl zur Messung von Lasten und Kräften als auch als Überlastschutz verwendet. Sie werden an Stelle normaler Bolzen oder Wellen als Konstruktionselement in Maschinen eingesetzt. Das Messsignal ist proportional zur einwirkenden Last. Die in der Schweiz hergestellten, kompakten Lastmessbolzen der Baureihe LB 200 werden aus hochfestem, rostfreiem Stahl gefertigt. Dadurch eignen sie sich speziell für anspruchsvolle, industrielle Einsätze. Die Lastmessbolzen sind in 10 verschiedenen Standardbereichen von 2.5 kN bis 1 250 kN erhältlich. Bedingt durch die hohe Flexibilität, lassen sich die Messbolzen kostengünstig und problemlos sowohl in neue als auch in bestehende Anlagen oder Maschinen einsetzen.

Konstruktion

Der Magtrol Lastmessbolzen ist mit zwei Einschnürungen und einer zentrischen axialen Bohrung versehen. Die DMS -Vollbrücke ist in der zentrischen Bohrung im Bereich der Einschnürungen positioniert (Doppel-Vollbrücke bei LB 230-Modellen). Die Lage und die Ausrichtung der in einer Vollbrücke geschalteten DMS wurde mittels der Methode der finiten Elemente (FEM) optimiert. Das Messsignal ist praktisch unempfindlich gegen seitlich oder axial auf den Lastmessbolzen einwirkende Kräfte.

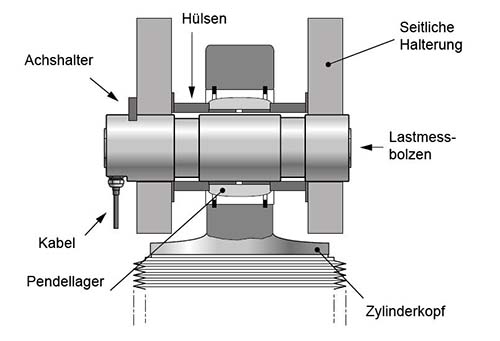

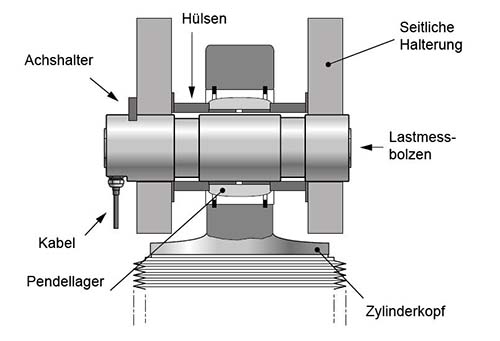

Montagebeispiel

Um ein individuelles Angebot für einen Lastmessbolzen entsprechend Ihrer Anwendungsdimensionen zu erhalten, füllen Sie bitte das Formular Lastmessbolzen-Anfrage aus.

Merkmale

- Erfassen von Überlast und Messung von Kräften von 2.5 kN … 1 250 kN.

- Zulässige Überlast : 150 % der Nennlast.

- Bruchlast : 500% der Nennlast.

- Unempfindlich gegen externe mechanische und chemische Einflüsse.

- Bestens geeignet für Einsätze in aggressiven Umgebungen.

- Temperaturkompensierte DMS-Vollbrückenaufnehmer. Auf Anfrage in redundanter Ausführung

mit zwei Messbrücken verfügbar. - Kostensparende Problemlösung dank einfacher Montage.

- Hohe Zuverlässigkeit bei strengen Sicherheitsanforderungen.

- Hohe Flexibilität dank modularer Konfektionierungsmöglichkeit der Standardmessbolzen.

- Sonderabmessungen zur Anpassung an bestehende Einbauverhältnisse.

Spezifikationen

| Model(s) | Nominal

Load

(kN) | Nominal

Load

(tf) | Nominal

Diameter

(mm) | Drawing | 3D Models

LB-210 Series

(PG Radial) | 3D Models

LB-210 Series

(PG Axial) |

|---|

| LB 210 | 2.5 | 0.28 | 25 | N/A | step | N/A |

LB 211

LB 231 | 5 | 0.56 | 25 | pdf | step | N/A |

LB 212

LB 232 | 10 | 1.12 | 25 | pdf | step | N/A |

LB 213

LB 233 | 20 | 2.25 | 25 | pdf | step | N/A |

LB 214

LB 234 | 50 | 5.62 | 35 | pdf | step | step |

| LB 235 | 70 | 7.87 | 45 | pdf | N/A | N/A |

LB 216

LB 236 | 100 | 11.24 | 50 | pdf | step | step |

LB 217

LB 237 | 200 | 22.48 | 65 | pdf | step | step |

LB 218

LB 238 | 500 | 56.20 | 85 | pdf | step | step |

LB 220

LB 240 | 1000 | 112.40 | 100 | pdf | step | step |

LB 221

LB 241 | 1250 | 140.50 | 120 | pdf | step | step |

TECHNISCHE DATEN – LB 210 REIHE

| STANDARDAUSFÜHRUNG a) | LB 210 | LB 211 | LB 212 | LB 213 | LB 214 | LB 216 | LB 217 | LB 218 | LB 220 | LB 221 |

|---|

| LASTMESSUNG |

| Nennlast (NL) b) | 2.5 kN | 5 kN | 10 kN | 20 kN | 50 kN | 100 kN | 200 kN | 500 kN | 1 000 kN | 1 250 kN |

| Zulässige Last (% der NL) | 150 % (der Nennlast, ohne Beeinflussung der Messresultate) |

| Bruchlast (% der NL) | > 500 % | 400 % | 300 % |

| Linearitätsfehler b) | < 0.25 % | < 0.5 % |

| Linearitäts- und Hysteresefehler b) | < 0.5 % | < 0.8 % |

| Reproduzierbarkeit b) | ± 0.1 % |

| MECHANISCHE EIGENSCHAFTEN UND UMGEBUNG |

| Funktionsprinzip | DMS-Vollbrücke |

| Material | Rostfreier Stahl 1.4057 |

| Schmierung | Nicht verfügbar | Oiler ø4 DIN 3405 D or M10 DIN 3405 A |

| Betriebstemperatur | - 25 °C ... + 80 °C |

| Lagerungstemperatur | - 55 °C ... + 125 °C |

| Temperatureinfluss (Nullpunkt) | ± 0.02 % / K |

| Temperatureinfluss (Empfindlichkeit) | ± 0.02 % / K |

| Passung | G7 / h6 |

| Einfluss α auf Messsignal c) | Nach Cosinus-Funktion |

| Schutzklasse | IP 66 entsprechend DIN 60529 |

| ELEKTRISCHE EIGENSCHAFTEN & ANSCHLUSS |

| Brückenimpedanz (Eingangswiderstand) | 400 Ω |

| Brückenimpedanz (Ausgangswiderstand) | 350 Ω |

| Speisung | 5 ... 12 VDC |

| Nullabgleich b) | ± 1 % |

| Aufnehmerempfindlichkeit | 0.5 mV/V ± 3 % | 1 mV/V ± 3 % | 1.8 mV/V ± 3 % |

| Ausgangsverbindung | Integriertes 3 m, 6 m, 12 m oder 20 m, Polymer-Kabel K-424 (Standard) e) |

| PG-Ausgang | Axial, mit Schrumpfschlauch | Radial, mit Schrumpfschlauch (Standard);

Axial, mit Schrumpfschlauch (Option) |

| Ausgangsstecker (Option) | Nicht verfügbar | Radial, Stecker: Souriau 851 02 E 10 6P50 |

| Anschlusskabel-Assembly (Option) | Nicht verfügbar | 3 m, 6 m, 12 m oder 20 m Kabel

mit axialer- oder 90° Stecker d) e) |

a) Die obigen Spezifikation gelten für Standard-Lastmessbolzen,

Spezialtypen auf Anfrage erhältlich.

b) Vom Endwert.

c) Meßsignaländerung an der Stellwinkel.

d) Axialer Stecker: Souriau 851 06 JC 10 6S50; 90° Stecker: Souriau 851 08 EC 10 6S50.

e) Andere mehr lange Kabel auf Anfrage erhältlich.

TECHNISCHE DATEN – LB 230 REIHE

| STANDARDAUSFÜHRUNG a) | LB 231 | LB 232 | LB 233 | LB 234 | LB 235 | LB 236 | LB 237 | LB 238 | LB 240 | LB 241 |

|---|

| LASTMESSUNG |

| Nennlast (NL)b) | 5 kN | 10 kN | 20 kN | 50 kN | 70 kN | 100 kN | 200 kN | 500 kN | 1 000 kN | 1 250 kN |

| Zulässige Last (% der NL) | 150 % (der Nennlast, ohne Beeinflussung der Messresultate) |

| Bruchlast (% der NL) | ≥ 500 % | 400 % | 300 % |

| Linearitätsfehler b) | < 0.25 % |

| Linearitäts- und Hysteresefehler b) | < 0.4 % |

| Reproduzierbarkeit b) | ± 0.1 % |

| MECHANISCHE EIGENSCHAFTEN UND UMGEBUNG |

| Funktionsprinzip | DMS-Vollbrücke (2x) |

| Material | Rostfreier Stahl 1.4057 |

| Betriebstemperatur | - 25 °C ... + 80 °C |

| Lagerungstemperatur | - 55 °C ... + 125 °C |

| Temperatureinfluss (Nullpunkt) | ± 0.02 % / K |

| Temperatureinfluss (Empfindlichkeit) | ± 0.02 % / K |

| Passung | G7 / h6 |

| Einfluss α auf Messsignal c) | Nach Cosinus-Funktion |

| Schutzklasse | IP 67 entsprechend DIN 60529 |

| SICHERHEITSSTANDARDS |

| OIML-Klasse | Nicht verfügbar | R60 D0.1 | Nicht verfügbar |

| ELEKTRISCHE EIGENSCHAFTEN & ANSCHLUSS |

| Brückenimpedanz (Eingangswiderstand) | 800 Ω |

| Brückenimpedanz (Ausgangswiderstand) | 700 Ω |

| Speisung | 5 ... 12 VDC |

| Nullabgleich b) | ± 1 % |

| Aufnehmerempfindlichkeit | 0.5 mV/V ± 3 % | 1 mV/V ± 3 % | 1.8 mV/V ± 3 % |

| Ausgangsverbindung | Integriertes 3 m, 6 m, 12 m oder 20 m, Polymer-Kabel K-824 (Standard) |

| Ausgangsstecker | Axialer Stecker, Souriau 8525 IH 10B06 PNH |

| Anschlusskabel (Option) | 3 m, 6 m, 12 m oder 20 m Kabel

mit axialer- oder 90° Stecker d) e) |

a) Die obigen Spezifikation gelten für Standard-Lastmessbolzen,

Spezialtypen auf Anfrage erhältlich.

b) Vom Endwert.

c) Meßsignaländerung an der Stellwinkel.

d) Axialer Stecker: Souriau 851 06 JC 10 6S50; 90° Stecker: Souriau 851 08 EC 10 6S50.

e) Andere mehr lange Kabel auf Anfrage erhältlich.

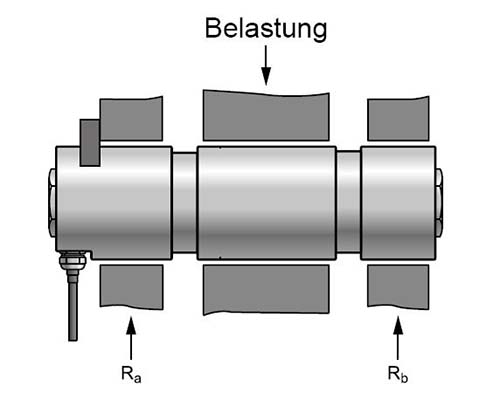

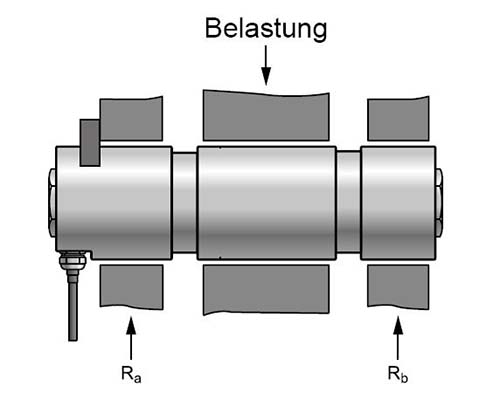

Funktionsprinzip

Bei Belastung des Lastmessbolzens in Messrichtung ergibt sich durch Verstimmung der DMS-Messbrücke ein Ausgangssignal, welches zu der einwirkenden Kraft proportional ist. Die Speisung der DMS-Brücke sowie die Verstärkung des Ausgangssignals (Spannung) erfolgen durch einen externen Verstärker, der je nach Ausführung die Überwachung mehrerer Grenzwerte ermöglicht.

Zwecks optimaler Belastung sollten Ra und Rb gleich gross sein.

Anwendungen

Sollen auf mechanische Bauelemente wirkende Kräfte gemessen werden, so erweisen sich die dazu üblicherweise benötigten Ausrüstungen als kostenintensiv und schwierig zu installieren. Die Lastmessbolzen von Magtrol stellen eine sehr elegante Lösung dar, da sie integriert als Konstruktionselement einen normalen Bolzen oder eine Welle ersetzen. Die LB 200 – Lastmessbolzen werden in Lastmessausrüstungen oder als Überlastschutz von Kränen, Hubwerken, Aufzügen und Seilwinden und zur Behälterverwiegung im Anlagebau eingesetzt. Weiter können sie auf Skilifts, Sesselliften und Seilbahnen zur Messung und Überwachung der Seilspannung, im Maschinenbau bei Stellgliedern, Zugspannungsregelungen und als Überlastschutz verwendet werden.

WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 1240

[1] => 1235

[2] => 1261

[3] => 1263

)

[post__not_in] => Array

(

[0] => 1157

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 1240

[1] => 1235

[2] => 1261

[3] => 1263

)

[post__not_in] => Array

(

[0] => 1157

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_9_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_9_posts.* FROM wp_9_posts WHERE 1=1 AND wp_9_posts.ID IN (1240,1235,1261,1263) AND wp_9_posts.post_type = 'product' AND (wp_9_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 1261

[post_author] => 1

[post_date] => 2017-04-10 12:07:43

[post_date_gmt] => 2017-04-10 12:07:43

[post_content] => Die GAD-Fernanzeige wird mit LMU-Lastmessverstärkern und AN-Digitalmonitoren eingesetzt. Ihre grossflächigen Ziffern eignen sich speziell für Gewichtsanzeigen bei Kränen, bei industriellen Prozessen und bei Wägeeinrichtungen mit Fernanzeige. Die dabei verwendete Mikroprozessortechnologie garantiert einen sehr zuverlässigen Betrieb. Sie ist mit einem nichtvolatilen Speicher für die Kalibrierungsdaten ausgerüstet.

Last-Kraft-Gewicht-System

Die GAD-Fernanzeigen werden als Teil eines kompletten Messsystems zusammen mit LMU Series Lastmessverstärkern oder AN Series Digitalmonitoren von Magtrol eingesetzt. Magtrol- Lastmessbolzen mit Überlastschutz zur Messung von Lasten und Kräften sowie ein breites Angebot an Last-Kraft-Gewicht-Aufnehmern stehen in den verschiedensten Ausführungen und Genauigkeitsklassen zur Verfügung. Kombiniert ergeben diese Produkte ein ideales, sicheres Messsystem zur dauernden Überwachung von Überlasten und Kurzschlüssen.

[post_title] => GAD Series - Grossflächige Fernanzeige

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => gad-series-large-remote-digital-displays

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-04 22:01:20

[post_modified_gmt] => 2024-04-04 20:01:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1261

[menu_order] => 75

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 1240

[post_author] => 1

[post_date] => 2017-04-10 11:57:22

[post_date_gmt] => 2017-04-10 11:57:22

[post_content] => LMU-Lastmessverstärker eignen sich speziell für Anwendungen mit Dehnmessstreifen. Speziellfür den Einsatz mit Lastmessbolzen und Last-Kraft-Gewicht-Aufnehmern bestimmt, liefert die Palette der Lastmessverstärker LMU die Erregerspannung und verstärkt gleichzeitig das Signal der Messbrücke.

Die Verwendung von Mikroschaltern und Reitern verleiht dem Gerät eine grosse Flexibilität und eine einfache Handhabung in der Inbetriebnahme (keine Lötverbindungen). Die Grenzwertüberwacher und Messverstärkerausgänge können dem Messbrückeneingang, dem Spannungseingang oder der Summe beider zugeordnet werden (siehe «Auswahl der Anwendung» oben auf Seite 4). Durch ständige Überprüfung des Systems können allfällige Kurzschlüsse oder Leitungsbrüche festgestellt werden, was einen Einsatz der Lastmessverstärker in Systemen erlaubt, bei welchen die Sicherheit einen hohen Stellenwert darstellt.Tritt ein Defekt auf, werden beide Relais desaktiviert, die Spannungsausgänge weisen dann Spannungen von mehr als 10 V DC und die Stromausgänge

Ströme von mehr als 20 mA auf.

Der LMU-Lastmessverstärker erfüllt alle CE-Normen. Dank dem Aluminiumgehäuse (Schutzklasse IP 65) kann der Lastmessverstärker auch in anspruchsvollen Umgebungsbedingungen verwendet werden. Die SMDTechnik (Surface Mounted Device), welche bei den LMU-Geräten eingesetzt wird, garantiert ein optimales Preis-/Leistungsverhältnis für Signalüberwachungen von Dehnmessstreifen.

[post_title] => LMU Reihe - Lastmessverstärker

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => load-monitoring-units-lmus

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 16:29:06

[post_modified_gmt] => 2024-02-23 15:29:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1240

[menu_order] => 67

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 1235

[post_author] => 1

[post_date] => 2017-04-10 12:01:17

[post_date_gmt] => 2017-04-10 12:01:17

[post_content] => Die Lastmonitore, Signalaufbereiter & Anzeigen AN Series von Magtrol werden zur Verarbeitung und Anzeige von Messwerten aus Signalen verwendet, die von Aufnehmern (Gewicht, Last, Druck, Drehmoment usw.) erzeugt werden, welche Brücken-Dehnungsmessstreifen verwenden. Zum Beispiele: die Lastmessbolzen LB Series, Miniatur-Lastmessbolzen MB-02 Series oder jede andere Art von Aufnehmern, die eine DMS-Brückentechnologie verwenden. Die Geräte AN Series eignen sich ideal für den Einsatz in Innenräumen. Sie bieten wählbare Eingangspegel für verschiedene Arten von Empfindlichkeiten und Erregerspannungen, die für eine unterschiedliche Anzahl von Zellen geeignet sind.

Bei bestimmten Konfigurationen (Signalverstärkung, Sicherheit, ...) ist es notwendig, den Konditionierer AN Series mit einem Lastmessverstärker LMU Series zu kombinieren. Wenn eine größere Anzeige oder eine Fernanzeige erforderlich ist, kann in Kombination eine große Anzeige GAD Series (mit Ziffernhöhen von 57 bis 400 mm) verwendet werden.

AN 1500 M : Lastmonitor, Signalaufbereiter & Anzeige

Als Signalaufbereiter wird der AN 1500 M zur Aufbereitung und Anzeige von Signalen verwendet, die von Sensoren (Kraft, Last, Druck, Drehmoment, ...) mit Dehnungsmessstreifen in Brückenschaltung stammen. Als Lastmonitor kann er auch jedes Signal im Bereich von ±150 mV DC von einem Shunt einem Konverter oder einer beliebigen Art von Transmitter empfangen.

Der Lastmonitor bietet wählbare Eingangsbereiche (±15 mV, ±30 mV, ±150 mV) und Erregerspannungen (5 V, 10 V), um Wägezellen mit verschiedenen Typen und Empfindlichkeiten zu unterstützen. Zwei Programmiermethoden ermöglichen die Skalierung des Messgeräts für den Betrieb in den gewünschten technischen Einheiten.

Das Basisgerät ist eine gelötete Baugruppe, die aus einer Hauptplatine, einer dreifarbigen programmierbaren Anzeige und einem Stromkreis besteht. Zu den Standardmerkmalen gehören das Ablesen der Eingangsvariablen sowie Fern- HOLD, das Ablesen und Speichern von Minimal-/Maximalwerten (PEAK / VALLEY), TARA- und Reset-Funktion und eine ganze Reihe von programmierbaren Logikfunktionen.

AN 2000 C : Signalaufbereiter & Anzeige

Der Signalaufbereiter und Anzeiger AN 2000 C wird zur Aufbereitung und Anzeige von Signalen verwendet, die von Sensoren (Kraft, Last, Druck, Drehmoment, ...) mit Dehnungsmessstreifen in Brückenschaltung stammen. Er kann auch jedes Signal im Bereich von ±300 mV DC von einem Shunt einem Konverter oder einer beliebigen Art von Transmitter empfangen.

Der Aufberieter bietet wählbare Eingangsbereiche (max. ±300 mV) und Erregerspannungen (5 V, 10 V), um Wägezellen mit verschiedenen Typen und Empfindlichkeiten zu unterstützen. Zwei Programmiermethoden ermöglichen die Skalierung des Messgeräts für den Betrieb in den gewünschten technischen Einheiten.

Das Basisgerät ist eine gelötete Baugruppe, die aus einer Hauptplatine, einer dreifarbigen programmierbaren Anzeige und einem Stromkreis besteht. Zu den Standardmerkmalen gehören das Ablesen der Eingangsvariablen sowie Fern- HOLD, das Ablesen und Speichern von Minimal-/Maximalwerten (PEAK / VALLEY), TARA- und Reset-Funktion und eine ganze Reihe von programmierbaren Logikfunktionen.

[post_title] => AN Series - Lastmonitor, Signalaufbereiter & Anzeige

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => an-series-load-conditioners-with-display

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 16:30:20

[post_modified_gmt] => 2024-02-23 15:30:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1235

[menu_order] => 74

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 3

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 1261

[post_author] => 1

[post_date] => 2017-04-10 12:07:43

[post_date_gmt] => 2017-04-10 12:07:43

[post_content] => Die GAD-Fernanzeige wird mit LMU-Lastmessverstärkern und AN-Digitalmonitoren eingesetzt. Ihre grossflächigen Ziffern eignen sich speziell für Gewichtsanzeigen bei Kränen, bei industriellen Prozessen und bei Wägeeinrichtungen mit Fernanzeige. Die dabei verwendete Mikroprozessortechnologie garantiert einen sehr zuverlässigen Betrieb. Sie ist mit einem nichtvolatilen Speicher für die Kalibrierungsdaten ausgerüstet.

Last-Kraft-Gewicht-System

Die GAD-Fernanzeigen werden als Teil eines kompletten Messsystems zusammen mit LMU Series Lastmessverstärkern oder AN Series Digitalmonitoren von Magtrol eingesetzt. Magtrol- Lastmessbolzen mit Überlastschutz zur Messung von Lasten und Kräften sowie ein breites Angebot an Last-Kraft-Gewicht-Aufnehmern stehen in den verschiedensten Ausführungen und Genauigkeitsklassen zur Verfügung. Kombiniert ergeben diese Produkte ein ideales, sicheres Messsystem zur dauernden Überwachung von Überlasten und Kurzschlüssen.

[post_title] => GAD Series - Grossflächige Fernanzeige

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => gad-series-large-remote-digital-displays

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-04 22:01:20

[post_modified_gmt] => 2024-04-04 20:01:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1261

[menu_order] => 75

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 0d1ef6d8cf2ae1a2e8294f556f0aa54e

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)