Product Description

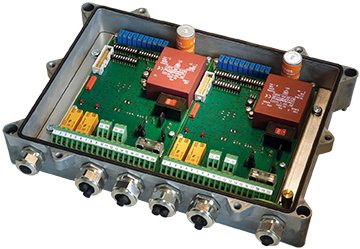

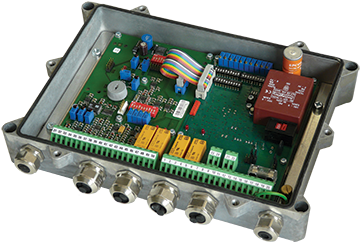

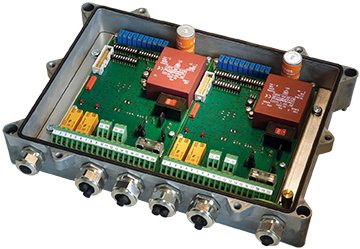

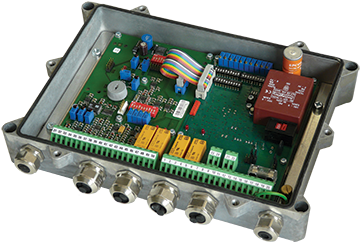

The Magtrol Load Monitoring Unit is specially designed for strain gauge transducer applications. Specifically developed for use with Magtrol load measuring pins and load-force weight sensors, the LMU Series provides excitation current and amplifies the output signal of full-bridge strain gauges.

Load Monitoring Units are flexible and fully configurable due to DIP-switches and jumpers which allow the unit to be easily installed – no solder connections are required. The level detectors and the outputs can be dedicated either to the full-bridge input, to the voltage input, or to the sum of both. A built-in auto-diagnostic system detects any short circuits or signal line failures, thus allowing the system to be used in applications where safety is important. If a problem is detected, both relays are deactivated and the output voltage (respective current) changes to > 10 V DC and > 20 mA.

The LMU is fully compatible with European Community (CE) standards. Its IP 65 aluminum housing allows the system to be used in harsh environments. Using SMD (surface mounted device) technology, the LMU allows the maximum performance/ price ratio for strain gauge transducer monitoring.

Features

- For use with full-bridge strain gauge transducers (sensitivity 0.5 to 4 mV / V)

- Voltage input for load summation or for individual use (without sensor)

- 2 to 4 level detectors with relay output contacts

- 0 – 20 mA or 4 – 20 mA DC current output

- ± 10 V voltage output(s)

- Provides continuous detection of signal line failure and short circuits («OK» signals)

- Includes integrated test equipment (B.I.T.E.) with continuous power supply monitoring

- Compatible to CE Standards

- IP 65 aluminum housing

Features of LMU 216 Only:

- 4 level detectors with output contacts, 2 of them with programmable memory

- 4 voltage inputs with summation

- TARE function

- Optional balancing and comparator sub-module

Model Comparison

|  |  |  |  |

| MODEL | LMU 209 | LMU 212 | LMU 217 | LMU 216 |

| Transducer Inputs | 1 | 1 | 2 | 1 |

| Voltage Output | 1 × 0–10 V | 1 × 0–10 V | 2 × 0–10 V | 3 × 0–10 V |

| Current Output | 1 × 0/4–20 mA | 1 × 0–20 mA or 4–20 mA | 2 × 0–20 mA or 4–20 mA | 1 × 0–20 mA or 4–20 mA |

| Relays | 0 | 2 | 4 | 4 |

| Summation | 0 | 2 | 3 | 4 |

| Power Supply | 18...28 VDC /

70 mA | 115–230 VAC (50–60 Hz)

20–32 VDC

48 VAC | 115–230 VAC (50–60 Hz)

20–32 VDC

48 VAC | 115–230 VAC (50–60 Hz)

20–32 VDC

48 VAC |

| Housing | PC-F, UL 94V-0

polycarbonate

Aluminum (option) | Aluminum | Aluminum | Aluminum |

| Protection Class | IP52 or

IP65 (option) | IP65 | IP65 | IP65 |

WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 1157

[1] => 1263

[2] => 1235

[3] => 1261

)

[post__not_in] => Array

(

[0] => 1240

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 1157

[1] => 1263

[2] => 1235

[3] => 1261

)

[post__not_in] => Array

(

[0] => 1240

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_10_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_10_posts.* FROM wp_10_posts WHERE 1=1 AND wp_10_posts.ID IN (1157,1263,1235,1261) AND wp_10_posts.post_type = 'product' AND (wp_10_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 1157

[post_author] => 1

[post_date] => 2017-04-07 18:37:19

[post_date_gmt] => 2017-04-07 18:37:19

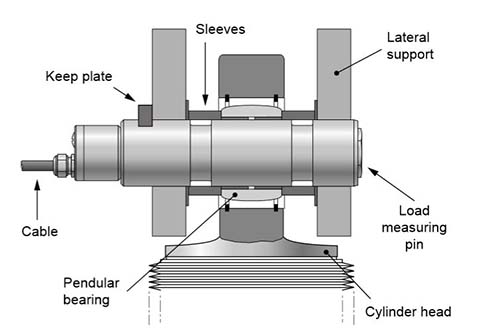

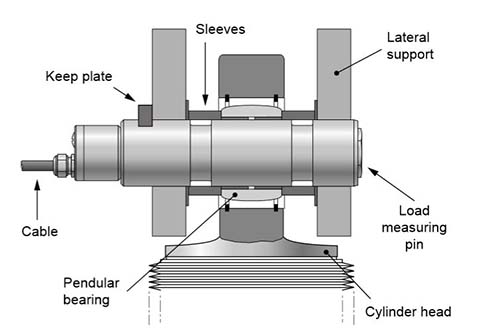

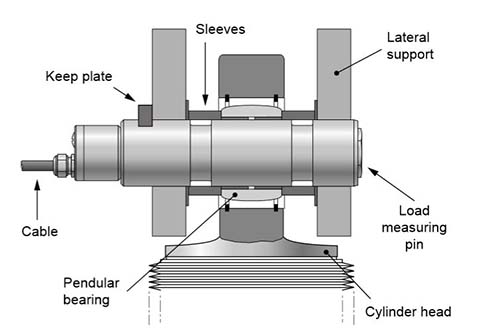

[post_content] => LB 200 Series Load Measuring Pins can be used alone or as part of a complete measurement system. Magtrol offers a wide range of Load-Force-Weight Transducers in various executions and accuracy classes and our Load Monitoring Units (LMUs) constitute an ideal safe measurement system which continuously checks for overloads and short circuits.

MAGTROL Load Measuring Pins are used to measure load and force and provide overload protection. The pins are mounted into machines in place of normal shafts and fitted with strain gauges, allowing them to produce a signal proportional to the measured load. Manufactured in Switzerland, Magtrol’s LB 200 Series Load Pins are rugged with high resistance stainless steel and tight construction, designed specifically for use in harsh industrial environments. Available in several standard ranges from 2.5 kN to 1250 kN, these highly ergonomic pins can be used for either new or refitted installations and are adaptable to various conditions.

Design

The Magtrol Load Pin has 2 circular grooves and an axial bore. Inside the central bore, adjacent to the external grooves, the strain gauges are mounted in a full-bridge configuration (double full-bridge for LB 230 models). The positioning and orientation of the strain gauges have been optimized by means of the finite element method (FEM). Any transverse or axial forces, even when acting on any part of the pin, have practically no influence on the measurement signal.

Receive a quotation for a load pin according to your application's dimensions by filling out our load pin inquiry form.

[post_title] => LB 200 Series - Load Measuring Pins

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => load-measuring-pins

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 20:56:04

[post_modified_gmt] => 2024-02-23 15:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1157

[menu_order] => 32

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 1235

[post_author] => 1

[post_date] => 2017-04-10 12:01:17

[post_date_gmt] => 2017-04-10 12:01:17

[post_content] => Magtrol’s AN Series Load Monitor, Signal Conditioner & Display are used for processing and displaying measurements from signals generated by transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges, such as Magtrol’s Load Measuring Pins LB Series(), Miniature Load Pins MB-02 Series() or any Custom Sensors based on strain gauge technology. The AN Series devices are suited for indoor use. These provides selectable input ranges and excitation voltages to accommodate cells of various types and sensitivities.

In some configurations (signal amplification, safety,...) it will be necessary to use the AN Series conditioner with a LMU Series - Load Monitoring Unit. If a remote or larger display is required a GAD Series - Digital Display (with heights ranging from 57 to 400 mm) can be used.

Receive a quotation for a load pin according to your application's dimensions by filling out our load pin inquiry form.

[post_title] => LB 200 Series - Load Measuring Pins

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => load-measuring-pins

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 20:56:04

[post_modified_gmt] => 2024-02-23 15:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1157

[menu_order] => 32

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 1235

[post_author] => 1

[post_date] => 2017-04-10 12:01:17

[post_date_gmt] => 2017-04-10 12:01:17

[post_content] => Magtrol’s AN Series Load Monitor, Signal Conditioner & Display are used for processing and displaying measurements from signals generated by transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges, such as Magtrol’s Load Measuring Pins LB Series(), Miniature Load Pins MB-02 Series() or any Custom Sensors based on strain gauge technology. The AN Series devices are suited for indoor use. These provides selectable input ranges and excitation voltages to accommodate cells of various types and sensitivities.

In some configurations (signal amplification, safety,...) it will be necessary to use the AN Series conditioner with a LMU Series - Load Monitoring Unit. If a remote or larger display is required a GAD Series - Digital Display (with heights ranging from 57 to 400 mm) can be used.

AN 1500 M: Load Monitor, Signal Conditioner & Display

As a Signal Conditioner, the AN 1500 M is designed to process and display signals coming from various types of transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges. As a Load Monitor the AN 1500 M can also receive any signal within the ± 150 mV DC range coming from a shunt, a converter or any type of transmitter.

The Load Monitor provides selectable input ranges (±15 mV, ±30 mV, ±150 mV) and excitation voltages (5 V, 10 V) to accommodate cells of various types and sensitivities. Two programming methods allow scaling of the meter to operate in the desired engineering units.

The basic instrument is a soldered assembly composed of a main board, a tri-color programmable display and a power circuit. Standard features include the reading of the input variable as well as remote (HOLD), the reading and memorization of minimum/maximum values (PEAK / VALLEY), TARE and RESET function, and a full complement of programmable logic functions.

AN 2000 C: Signal Conditioner & Display

The AN 2000 C Signal Conditioner & Display is designed to process and display signals coming from various types of transducers (weight, load, pressure, torque, etc.) that use standard strain-gauge bridges. It can also receive any signal within the range ± 300 mV DC coming from a shunt, a converter or any type of transmitter.

The Conditioner provides selectable input ranges (max. ±300 mV) and excitation voltages (5 V, 10 V) to accommodate cells of various types and sensitivities. Two programming methods allow scaling of the meter to operate in the desired engineering units.

The basic instrument consists of a PCB assembly including the main board, the display and the power supply filter, to which the A/D conversion circuit and the input option are added.

The functions of the basic instrument include the display of the input variable as well as the remote freezing of the display (HOLD), the reading of the stored minimum and maximum values (PEAK & VALLEY) and the TARE function with reset to zero.

[post_title] => AN Series - Load Monitor, Signal Conditioner & Display

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => an-series-load-conditioners-with-display

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 21:00:44

[post_modified_gmt] => 2024-02-23 15:30:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1235

[menu_order] => 73

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 1261

[post_author] => 1

[post_date] => 2017-04-10 12:07:43

[post_date_gmt] => 2017-04-10 12:07:43

[post_content] => These high quality, large character digital displays can be used for crane weight display, process weight display, and all other remote weighing applications. They use microprocessor based technology for high reliability and have a non-volatile memory to store all the calibration data.

Load-Force-Weight Systems

Magtrol Large Digital Displays are used with Load Monitoring Units (LMUs) or signal conditioners (AN Series), as part of a complete measurement system. Magtrol load measuring pins, which measure load and force to provide overload protection, are available for a wide range of Load-Force-Weight, and in various executions and accuracy classes. Combined, these products constitute an ideal safe measurement system for continuous overload monitoring.

[post_title] => GAD Series - Large Remote Digital Displays

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => gad-series-large-remote-digital-displays

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-05 01:29:07

[post_modified_gmt] => 2024-04-04 19:59:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1261

[menu_order] => 74

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 3

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 1157

[post_author] => 1

[post_date] => 2017-04-07 18:37:19

[post_date_gmt] => 2017-04-07 18:37:19

[post_content] => LB 200 Series Load Measuring Pins can be used alone or as part of a complete measurement system. Magtrol offers a wide range of Load-Force-Weight Transducers in various executions and accuracy classes and our Load Monitoring Units (LMUs) constitute an ideal safe measurement system which continuously checks for overloads and short circuits.

MAGTROL Load Measuring Pins are used to measure load and force and provide overload protection. The pins are mounted into machines in place of normal shafts and fitted with strain gauges, allowing them to produce a signal proportional to the measured load. Manufactured in Switzerland, Magtrol’s LB 200 Series Load Pins are rugged with high resistance stainless steel and tight construction, designed specifically for use in harsh industrial environments. Available in several standard ranges from 2.5 kN to 1250 kN, these highly ergonomic pins can be used for either new or refitted installations and are adaptable to various conditions.

Design

The Magtrol Load Pin has 2 circular grooves and an axial bore. Inside the central bore, adjacent to the external grooves, the strain gauges are mounted in a full-bridge configuration (double full-bridge for LB 230 models). The positioning and orientation of the strain gauges have been optimized by means of the finite element method (FEM). Any transverse or axial forces, even when acting on any part of the pin, have practically no influence on the measurement signal.

Receive a quotation for a load pin according to your application's dimensions by filling out our load pin inquiry form.

[post_title] => LB 200 Series - Load Measuring Pins

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => load-measuring-pins

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 20:56:04

[post_modified_gmt] => 2024-02-23 15:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1157

[menu_order] => 32

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4701031fb54f22033bfbba692fa68a97

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

Receive a quotation for a load pin according to your application's dimensions by filling out our load pin inquiry form.

[post_title] => LB 200 Series - Load Measuring Pins

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => load-measuring-pins

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-23 20:56:04

[post_modified_gmt] => 2024-02-23 15:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=1157

[menu_order] => 32

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4701031fb54f22033bfbba692fa68a97

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

Receive a quotation for a load pin according to your application's dimensions by filling out our

Receive a quotation for a load pin according to your application's dimensions by filling out our