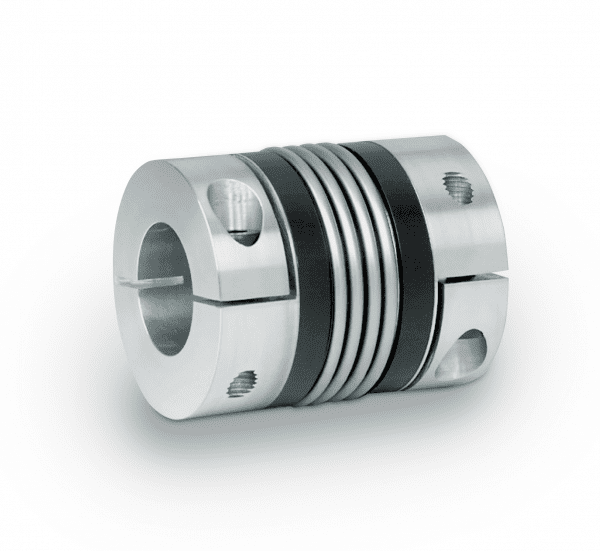

Product Description

BK2 Series Metal Bellows Couplings provide the ideal complement to Magtrol’s s TM / TMB / TMHS / TS In-Line Torque Transducers and Sensors, when these are to be mounted in a drive train.

The torque transmission element consists of a metal bellows and 2 clamping hubs. The couplings are both torsionally stiff and flexible in order to compensate for axial, angular and radial misalignment when connecting two shaft ends. The high torsional spring rate of the couplings ensures a high torsional stiffness and angular precision.

Design & Material

Bellows couplings are made of highly flexible and high-grade stainless steel. The hub material is made of aluminum or steel (please see “Specifications” section).

Clamping is done by a single ISO 4762 radial clamping screw per hub. For model 1500 and 4000, the clamping is performed by two opposite screws at 180 degrees.

Specifications

| Coupling Model | BK2 30-69 | BK2 60-83 | BK2 80-94 | BK2 150-95 | BK2 300-111 | BK2 1500-166 | BK2 4000-225 |

|---|

| Torque Transducers | TM/TMB/TMHS 309

TS 109 | TM/TMB/TMHS 309

TS 109 | TM/TMB/TMHS 310

TS 110 | TM/TMB/TMHS 311

TS 111 | TM/TMB/TMHS 312

TS 112 | TM/TMB/TMHS 314

TS 114 | TM/TMB/TMHS 315

TS 115 |

| RATINGS |

| Rated Torque | 30 N·m | 60 N·m | 80 N·m | 150 N·m | 300 N·m | 1500 N·m | 4000 N·m |

| Maximum Torque a) | 45 N·m | 90 N·m | 120 N·m | 225 N·m | 450 N·m | 2250 N·m | 6000 N·m |

| Maximum Speed b) | 10 000 rpm |

| MISALIGNMENT |

| Axial | 1 mm | 1.5 mm | 2 mm | 2 mm | 2.5 mm | 3.5 mm | 3.5 mm |

| Radial | 0.2 mm | 0.2 mm | 0.2 mm | 0.2 mm | 0.25 mm | 0.35 mm | 0.40 mm |

| Angular | 1 degree | 1 degree | 1 degree | 1 degree | 1 degree | 1.5 degree | 1.5 degree |

| STIFFNESS & INERTIA |

| Torsional Stiffness/Torsional Spring Rate | 39 × 103 N·m/rad | 76 × 103 N·m/rad | 129 × 103 N·m/rad | 175 × 103 N·m/rad | 450 × 103 N·m/rad | 1 304 × 103 N·m/rad | 3 400 × 103 N·m/rad |

| Axial spring stiffness | 50 N/mm | 72 N/mm | 48 N/mm | 82 N/mm | 105 N/mm | 320 N/mm | 565 N/mm |

| Lateral spring stiffness | 900 N/mm | 1 200 N/mm | 920 N/mm | 1 550 N/mm | 3 750 N/mm | 3 600 N/mm | 6 070 N/mm |

| Moment of Inertia | 0.12 × 10-3 kg·m² | 0.32 × 10-3 kg·m² | 0.8 × 10-3 kg·m² | 1.9 × 10-3 kg·m² | 7.6 × 10-3 kg·m² | 43 × 10-3 kg·m² | 165 × 10-3 kg·m² |

| MECHANICAL CHARACTERISTICS & ENVIRONMENT |

| Temperature Range | -30 ... +100 °C |

| Diameter Range c) | 10 ... 30 ø[mm]H7 | 12 ... 35 ø[mm]H7 | 14 ... 42 ø[mm]H7 | 19 ... 42 ø[mm]H7 | 24 ... 60 ø[mm]H7 | 50 ... 80 ø[mm]H7 | 50 ... 90 ø[mm]H7 |

| Hub material | Aluminium | Steel |

| Approximate Weight | 0.26 kg | 0.48 kg | 0.8 kg | 1.85 kg | 4 kg | 11.5 kg | 28.8 kg |

a) Brief overloads, acceptable up to 1.5 times the rated torque.

b)Higher speed available on request.

c) The standard versions are manufactured with integer values; the standard tolerance is H7. All diameters and tolerances are possible, within the defined max. range. Please contact our sales department.