What is a Torque Meter?

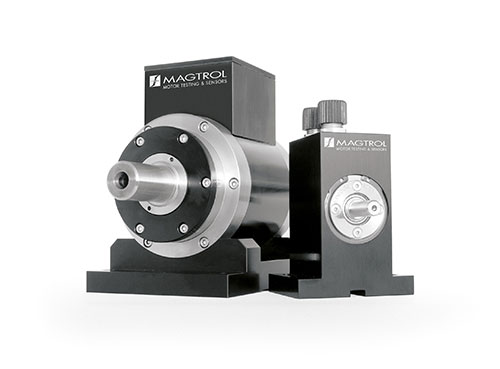

A torque meter, also called a torque sensor or torque transducer, is a device used to measure the rotational force (torque) applied to a shaft, bolt, or mechanical system. Torque meters play a critical role in industries such as automotive, aerospace, manufacturing, and research to ensure precision and performance in mechanical operations.

Why is Torque Measurement Important?

Torque measurement is essential for:

Quality Control: Ensures fasteners, motors, and rotating components meet precise torque specifications.

Efficiency Optimization: Helps improve system performance by measuring torque accurately.

Predictive Maintenance: Detects mechanical wear and prevents failures before they occur.

Safety Assurance: Reduces maintenance costs by preventing major breakdowns.

Research & Development: Provides data for engineering analysis and product innovation.

Types of Torque Meters

Torque meters come in various types, depending on the measurement method and application:

Rotary Torque Sensors: Measure dynamic torque in rotating systems like engines, turbines, and motors.

Reaction Torque Sensors: Measure static torque without rotation, often used in testing and calibration.

Inline Torque Transducers: Installed between shafts to continuously measure torque in real-time.

Handheld Torque Meters: Portable devices used for field testing and quality checks.

How Does a Torque Meter Work?

Torque meters operate by detecting the strain in a rotating or static component when torque is applied. The process typically involves:

Installation: The torque meter is mounted between the driving and driven components.

Calibration & Zeroing The device is calibrated to ensure accurate readings.

Data Collection: The torque meter captures real-time torque values during operation.

Analysis & Adjustment Engineers analyze the data to optimize system performance and detect anomalies.

Software Integration: Advanced torque meters work with digital controllers and data acquisition systems for precise monitoring and control.

Frequently Asked Questions

What factors affect torque measurement accuracy?

Temperature, mounting conditions, and calibration precision can all impact torque measurement accuracy.

How often should a torque sensor be calibrated?

Regular calibration is recommended, typically every 6-12 months, depending on usage and industry standards.

Can torque meters measure both static and dynamic torque?

Yes, reaction torque meters measure static torque, while rotary torque meters measure dynamic torque in real-time.

What is the best torque meter for my application?

The best torque meter depends on your torque range, rotational speed, and data output needs. Contact us for expert guidance.

Get the Best Torque Measurement Solutions

We provide high-quality torque meters, transducers, and digital controllers for precise torque measurement across industries. Whether you need a custom torque solution or want to upgrade your existing system, we’re here to help.

Ready for your solution?

Contact us today.