DSP7010 Series – Dynamometer Controller

Product Description

Magtrol’s DSP 7010 Series – Dynamometer Controller employs advanced Digital Signal Processing technology to provide superior motor testing capabilities. Designed for use with any Magtrol Hysteresis, Eddy-Current or Powder Dynamometer, Magtrol In-Line Torque Transducer or auxiliary instrumentation, the DSP 7010 can provide complete PC control via the USB or GPIB interface. With up to 488 readings per second, the DSP 7010 is ideally suited for both the test lab and the production line.

Features

- DSP7011 Single Channel: Cost-effective & User-friendly

- DSP7012 Dual Channel: Versatile with complete functionality; allows two fully independent configurations

- Speed & Torque Operating Modes: Provides independent PID settings for improved Dynamometer control

- Built-In Alarm System: power, speed, torque, temperature, air flow, water flow, electrical overload and external inputs

- Can be used independently or, ideally, in combination with Magtrol software to meet all requirements of motor testing

- High Speed Data Acquisition: ≤ 488 samplings / second (torque, speed, time, angle, etc.)

- Fast Full-Curve Data Acquisition: Free-run to locked rotor in seconds

- Programmable Digital PID Values: Controlled and stored via M-TEST Software or controlled manually

- Built-in Current-Regulated Supply: ≤ 1A

- Selectable Torque Units: Imperial, Metric and SI

- Digital Filter for Torque Signals

- PC Connection: USB & GPIB (IEEE-488.2)

- Position Measurement: two quadrature decoders

- Built-in I/O card accessible with software

- Operation via frontpanel keyboard computer

- High Quality, Easy-to-Read Vacuum Fluorescent Readout

- Desktop Housing or Rack Mounting (19″ / 2U)

- Command Compatible: compatible with the DSP 7000

Specifications

| MEASUREMENT CHARACTERISTICS |

| Maximum Torque |

99 999 units |

| Maximum Speed |

199 999 RPM |

| Torque Accuracy |

2 V range ±0.01 % of range (±0.2 mV) (used on all HD Series other than HD 5 Series)

10 V range ±0.01% of range (±1 mV) (used on all except HD Series) |

| Speed Accuracy |

0.01 % of reading from 5 ... 199 999 rpm |

| ELECTRICAL CHARACTERISTICS |

| Voltage Requirements

|

85-264 VAC 50/60 Hz |

| Power Requirements |

210 VA |

| Fuses (5 × 20 mm) |

IEC T 2.5 A 250 V L

|

| Max. Compliance Voltage |

48 V DC, Brake Output |

| Max. Brake Output Current |

1 Amp, Calibrated that 100% open loop = 1 Amp |

| TSC Power Supplies |

Torque Sensor: 24 V DC, max. 200 mA (power supply fault protected)

Encoder: 5 V DC, max. 200 mA (internal fuse at 500 mA) |

| ENVIRONMENT |

| Operating Temperature |

5 ºC ... 40 ºC |

| Relative Humidity |

< 80% |

| Temperature Coefficient |

0.004% of range/°C of 5 V DC for both channels |

| Altitude |

max. 2 000 m |

Applications

In the laboratory, the DSP7010’s high sample rate provides superior resolution for data acquisition and curve plotting. This allows capturing more usable motor test data during switching, breakdown and other transitional areas of the motor test curve. For production and incoming inspection, the DSP7010 displays torque, speed and power at all times, allowing the Controller to be used as a manual stand-alone unit or as part of a complete PC system.

WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 570

[1] => 856

[2] => 515

[3] => 891

)

[post__not_in] => Array

(

[0] => 9308

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 570

[1] => 856

[2] => 515

[3] => 891

)

[post__not_in] => Array

(

[0] => 9308

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_10_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_10_posts.* FROM wp_10_posts WHERE 1=1 AND wp_10_posts.ID IN (570,856,515,891) AND wp_10_posts.post_type = 'product' AND (wp_10_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 570

[post_author] => 1

[post_date] => 2017-04-05 14:52:14

[post_date_gmt] => 2017-04-05 14:52:14

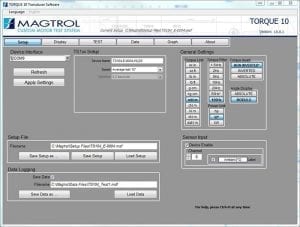

[post_content] => Magtrol’s TORQUE 10 Software is an easy to use Windows® executable program, used to automatically collect torque, speed, mechanical power and angle data from Magtrol TS Series Torque Sensors or Magtrol TM Series Torque Sensors by using Model 3411 Torque Display. The data can be printed, displayed graphically or quickly saved/exported as a Microsoft® Excel spreadsheet.

[table id=115 /]

Ordering Information

TORQUE 10 is now included with the purchase of a TS Series Torque Sensor or Model 3411 Torque Display.

[post_title] => TORQUE 10 - Software

[post_excerpt] => Download Torque 10 Software

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => torque-10-software

[to_ping] =>

[pinged] =>

[post_modified] => 2023-08-08 23:29:47

[post_modified_gmt] => 2023-08-08 17:59:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=570

[menu_order] => 31

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 515

[post_author] => 1

[post_date] => 2017-04-05 13:48:34

[post_date_gmt] => 2017-04-05 13:48:34

[post_content] => Finally… a Micro Dyne system designed specifically for your micro motors!

With over 50 years’ experience in dynamometer design and torque measurement, Magtrol has revolutionized the industry. Magtrol’s new Micro Dyne, capable of measuring extremely low torques (2.0 mN·m can be resolved to 0.0004 mN·m), is designed exclusively for testing miniature and micro motors.

For the utmost convenience, the Micro Dyne is packaged as a complete motor testing system. Everything that is needed to accurately and efficiently test miniature motors and micro motors is included with the purchase of a Magtrol Micro Dyne. The only component that needs to be supplied by the customer is a laptop or desktop personal computer and a motor power supply.

[post_title] => Micro Dyne System

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => micro-dyne-system

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:45:58

[post_modified_gmt] => 2023-04-21 15:15:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=515

[menu_order] => 42

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 856

[post_author] => 1

[post_date] => 2017-04-06 16:49:06

[post_date_gmt] => 2017-04-06 16:49:06

[post_content] => Originally designed to test window lift gear motors, Magtrol’s FMF Series Fixed Motor Fixtures are used to secure motors in place while running any test. These versatile fixtures align the motor under test with Magtrol’s HD-100, HD-106, HD-400, HD-500, HD-700 and HD-800 Series Dynamometers for easy setup and coupling—couplings can be provided upon request. Various adaptor rings (sold separately) can be customized to allow several different motors to be tested on the same fixture.

FMF Fixed Motor Fixtures can be mounted to any Magtrol Dynamometer T-slotted long base plate or any Hysteresis Dynamometer Table with grooved table top (TAB 1457S, TAB 0800L and TAB 0825L). These fixtures are equipped with a precisely located rectangular key on the bottom of the plate for easy centering. Also included are four adjustable clamping levers and T-nuts.

[post_title] => FMF Series - Fixed Motor Fixtures

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => fmf-fixed-motor-fixtures

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:55:11

[post_modified_gmt] => 2023-04-21 15:25:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=856

[menu_order] => 61

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 891

[post_author] => 1

[post_date] => 2017-04-06 17:36:16

[post_date_gmt] => 2017-04-06 17:36:16

[post_content] => Magtrol offers these calibration beam assemblies and weights for calibrating HD-Series Hysteresis Dynamometers. To perform a successful dynamometer calibration, precision weights heavy enough to apply a torque at or close to the full scale rating are required. Magtrol WT Series Calibration Weights are equal to the dynamometer's torque value, divided by the distance between the outer pin and centerline of the corresponding CB Series Calibration Beam. Calibration Weights are available in English or SI units. Calibration Beams are marked for both English and SI weights. For detailed dimension drawings, click on the model's underlined link. A PDF document will open in a new window.(Adobe Acrobat Reader 7.0, or later, is required.)

[post_title] => Calibration Beams and Weights

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => calibration-beams-and-weights

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 21:01:19

[post_modified_gmt] => 2023-04-21 15:31:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=891

[menu_order] => 113

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 570

[post_author] => 1

[post_date] => 2017-04-05 14:52:14

[post_date_gmt] => 2017-04-05 14:52:14

[post_content] => Magtrol’s TORQUE 10 Software is an easy to use Windows® executable program, used to automatically collect torque, speed, mechanical power and angle data from Magtrol TS Series Torque Sensors or Magtrol TM Series Torque Sensors by using Model 3411 Torque Display. The data can be printed, displayed graphically or quickly saved/exported as a Microsoft® Excel spreadsheet.

[table id=115 /]

Ordering Information

TORQUE 10 is now included with the purchase of a TS Series Torque Sensor or Model 3411 Torque Display.

[post_title] => TORQUE 10 - Software

[post_excerpt] => Download Torque 10 Software

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => torque-10-software

[to_ping] =>

[pinged] =>

[post_modified] => 2023-08-08 23:29:47

[post_modified_gmt] => 2023-08-08 17:59:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=570

[menu_order] => 31

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 3ebcd40088aec0a124a6302865f0413f

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)