Product Description

FEATURES

- 2 Models with maximum Torque: 400 mN·m & 800 mN·m

- Speed: up to 80 000 rpm

- Power: 0.5 kW & 1 kW

- Low Moment of Inertia

- Stable & smooth Braking Torque

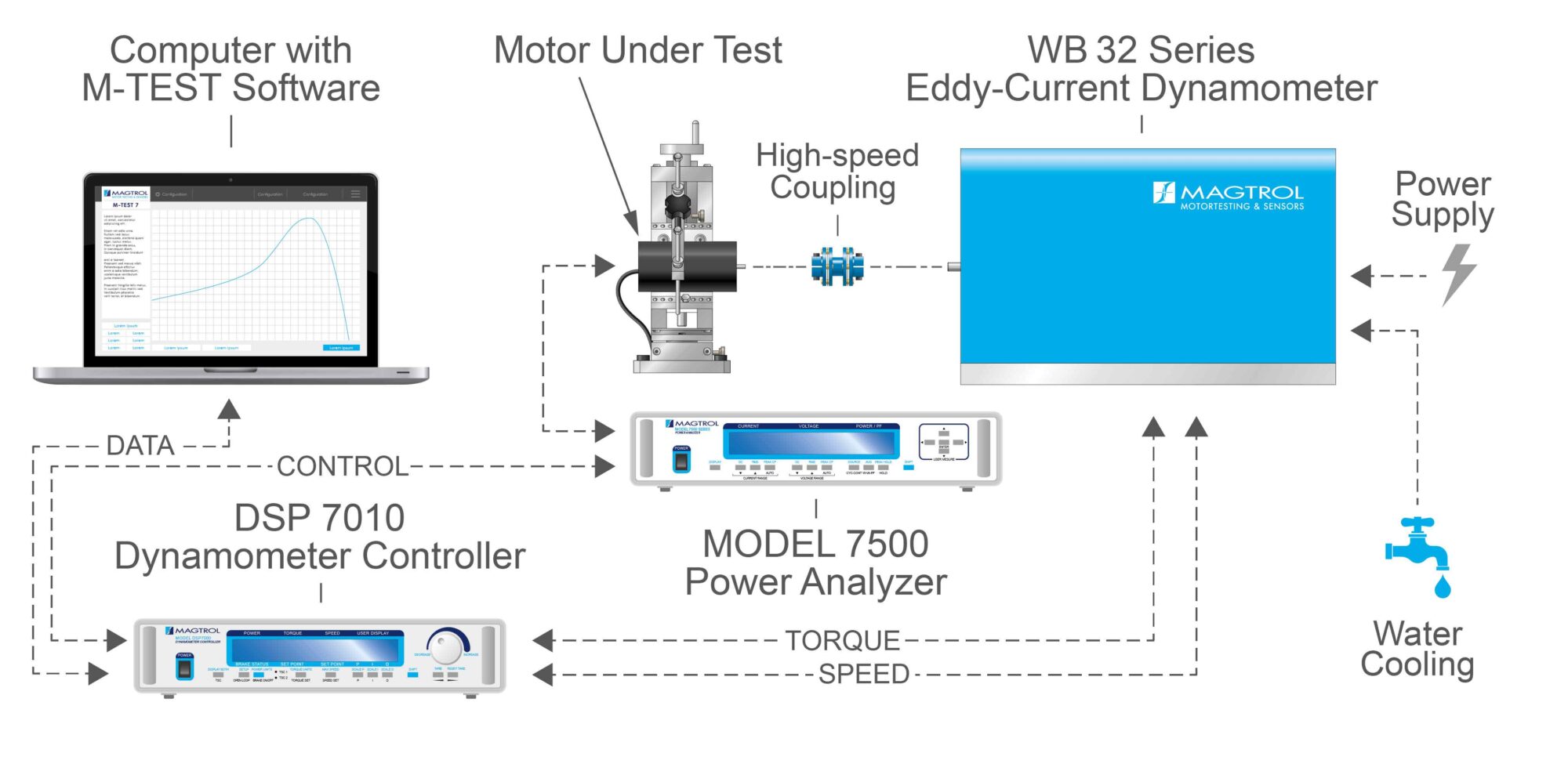

- Data acquisition via DSP 7010 Series Controller & M-TEST Software

- Built-in Electronics with Torque & Speed Measurement and Excitation Supply

DESCRIPTION

Magtrol’s WB 32 Series – Eddy-Current Dynamometers are designed for high-speed testing applications.They are ideal for applications requiring high speeds and also when operating in the lower power range (up to 1 kW). By providing a braking torque that is proportional to the rotational speed, rated torque is reached at the rated speed.

The Dynamometers feature a low level of inertia, due to small rotor dimensions. Brake cooling (required) is provided by a water circulation system, which passes inside the stator to dissipate heat generated by braking; this enables higher continuous power ratings.

The stator is mounted on carrier bearings and the torque is measured by the reaction torque sensor protected by overload limiter and transport locking device. The dynamometer has a torque measuring accuracy rating of ± 0.5 % full scale. The speed is measured by an optical sensor and a 4 PPR (Pulses Per Revolution) encoder. This sensor measures speeds form 100 … 80 000 rpm with a full scale accuracy of ± 0.06 % by using a Magtrol DSP 7010 Series Dynamometer Controller (due to encoder 4 PPR, the system is not suitable for precise closed-loop control below 1 000 rpm).

A Thermal Switch monitors the brake temperature and alarms the Controller (DSP 7010 Series) to stop the brake excitation current in order to protect the dynamometer from overheating.

OPERATING PRINCIPLES

The WB 32 Eddy-Current Dynamometers provide their full braking power at high speed. This type of brake has been specially designed to test motors rotating at speeds up to 80 000 rpm (100 000 rpm with WB 23/27, see specific datasheet), with the braking torque dependent upon the rotation speed.

APPLICATIONS

Mounted on test benches, the WB 32 Series Dynamometers allow performance and reliability testing on driving elements such as servomotors, micro and small motors, drone motors, fans, drills, hobby tools, small pumps, spindles, motors for domestic appliances, etc.

System Configuration

Specifications

| MODEL |

RATED TORQUE

[N·m] |

DRAG TORQUE

DE-ENGERGIZED

[mN·m] |

NOMINAL INPUT

INERTIA

[kg·m2] |

RATED POWER

[W] |

RATED SPEED

[rpm] |

MAX. SPEED

[rpm] |

EXCITATION

CURRENT

[A] |

DRAWING |

| 1WB32 |

0.4 |

< 20

(at 80 000 rpm) |

2.71 x 10-5 |

500 |

11 950 |

80 000 |

0.7 |

pdf | step |

| 2WB32 |

0.8 |

< 20

(at 80 000 rpm) |

5.03 x 10-5 |

1 000 |

11 950 |

80 000 |

1.4 |

pdf | step |

Complete System

The WB32 dynamometer can be integrated as a component of a measurement system.

The WB32 dynamometer can be integrated as a component of a measurement system.

Magtrol offers a standard version integrating the dynamometer on a base plate. The standard plate has 4 T-Slots to facilitate the attachment of other components and an ergonomic protective cover for the safety of the user.

As an option, the system can also be supplied with an AMF-1 Adjustable Motor Fixture. This allows test mounting and alignment of devices with diameters up to 100mm and 4.5kg.

Other designs and mounting systems are available on request. Please, contact our sales department for custom designs. Magtrol is at your service, and has a long experience in providing customized solutions.

Dynamometer Selection

Magtrol Dynamometers cover a wide range of Torque, Speed and Mechanical Power ratings. To select the appropriate size Dynamometer for your motor testing needs, you will need to determine the Maximum Torque, Speed and Power applied to the Dynamometer:

Maximum Torque

It is important to consider all torque points that are to be tested, not only rated torque, but also Locked Rotor and Breakdown Torque. Dynamometer selection should initially be based on the maximum torque requirement, subject to determining the maximum power requirements.

Maximum Speed

This rating is to be considered independent of torque and power requirements, and is the maximum speed at which the Dynamometer can be safely run under free run or lightly loaded conditions. It is not to be considered as the maximum speed at which full braking torque can be applied.

Maximum Power Ratings

These ratings represent the maximum capability of the Dynamometer Braking System to absorb and dissipate heat generated when applying a braking load to the motor under test. The power absorbed and the heat generated by the Dynamometer is a function of the Torque (T) applied to the motor under test, and the resulting speed (n) of the motor. This is expressed in these power (P) formulas:

| SI: |

P (watts) |

= |

T (N·m) |

x |

n (rpm) |

x |

(1.047 × 10-1) |

| English: |

P (watts) |

= |

T (lb·in) |

x |

n (rpm) |

x |

(1.183 × 10-2) |

| Metric: |

P (watts) |

= |

T (kg·cm) |

x |

n (rpm) |

x |

(1.027 × 10-2) |

All of Magtrol's controllers, readouts and software calculate horsepower

as defined by 1 hp = 550 lb·ft / s. Using this definition: |

|

hp |

= |

P (watts) |

/ |

745.7 |

| To calculate power, use Magtrol's online motor power calculator |

The Dynamometer’s ability to dissipate heat is a function of how long a load will be applied. For this reason, the Maximum Power ratings given are based on continuous operation under load, as well as a maximum of 5 minutes under load.

To safely dissipate heat and avoid Dynamometer failure, the maximum power rating

is the most important consideration in selecting a Dynamometer.

WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 410

[1] => 515

[2] => 512

[3] => 8320

[4] => 507

)

[post__not_in] => Array

(

[0] => 9785

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 410

[1] => 515

[2] => 512

[3] => 8320

[4] => 507

)

[post__not_in] => Array

(

[0] => 9785

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_10_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_10_posts.* FROM wp_10_posts WHERE 1=1 AND wp_10_posts.ID IN (410,515,512,8320,507) AND wp_10_posts.post_type = 'product' AND (wp_10_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 410

[post_author] => 1

[post_date] => 2017-04-05 12:20:44

[post_date_gmt] => 2017-04-05 12:20:44

[post_content] => Hysteresis Brake Dynamometers (HD Series) are versatile and ideal for testing in the low to medium power range (maximum 14 kW intermittent duty). With a Hysteresis Braking system, the Dynamometers do not require speed to create torque, and therefore can provide a full motor ramp from free-run to locked rotor. Brake cooling is provided by convection (no external source), by compressed air or by dedicated blower, depending on the model. All Magtrol Hysteresis Dynamometers have accuracy ratings of ± 0.25% full scale — depending on size and system configuration.

Features

- 16 Standard Models with Maximum Torque from 2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

- Hysteresis Braking System: Provides precise torque loading independent of shaft speed

- Motor Testing from No Load to Locked Rotor

- Accuracy: ±0.25% (Full Scale)

- Air Flow Sensor: For protection against overheating and operator error

- Standard Torque Units: English, Metric and SI

- Custom Dynamometers: for special torque and speed requirements

- Easy Calibration

The Hysteresis Braking System

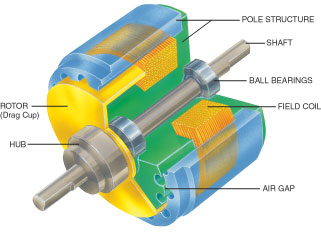

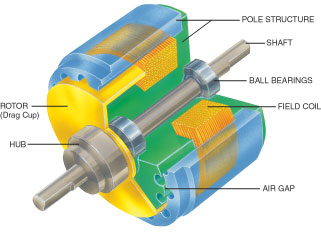

All Magtrol Hysteresis Dynamometers absorb power with a unique Hysteresis Braking System which provides frictionless torque loading independent of shaft speed. The Hysteresis Brake provides torque by the use of two basic components - a reticulated pole structure and a specialty steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from the field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 515

[post_author] => 1

[post_date] => 2017-04-05 13:48:34

[post_date_gmt] => 2017-04-05 13:48:34

[post_content] => Finally… a Micro Dyne system designed specifically for your micro motors!

With over 50 years’ experience in dynamometer design and torque measurement, Magtrol has revolutionized the industry. Magtrol’s

new Micro Dyne, capable of measuring extremely low torques (2.0 mN·m can be resolved to 0.0004 mN·m), is

designed exclusively for testing miniature and micro motors.

For the utmost convenience, the Micro Dyne is packaged as a

complete motor testing system. Everything that is needed to accurately and efficiently test miniature motors and micro motors is included with the purchase of a Magtrol Micro Dyne. The only component that needs to be supplied by the customer is a laptop or desktop personal computer and a motor power supply.

[post_title] => Micro Dyne System

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => micro-dyne-system

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:45:58

[post_modified_gmt] => 2023-04-21 15:15:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=515

[menu_order] => 42

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => The Powder Brake Dynamometer (PB Series) contains, as its name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction. They are ideal for applications operating in the low to middle speed range or when operating in the middle to high torque range. Like

Hysteresis Brakes, Powder Brakes provide full torque at zero speed. Like the

Eddy-Current Brake Dynamometers, the PB series are water-cooled, allowing for power ratings up to 48 kW. The PB Dynamometers have accuracy ratings of ± 0.3% to 0.5% full scale, depending on size and system configuration.

Features

- 9 Models with Maximum Torque from 5 N·m to 1 200 N·m (3.69 lb·ft to 885 lb·ft)

- Braking Power: 500 W to 48 kW

- Stable Braking Torque

- Low Moment of Inertia

- Operation in Either Rotational Direction

- Braking Torque Measurement Integrated

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The PB Series - Powder Dynamometers contain, as their name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction between rotor and stator. The Powder Dynamometers (PB) produce their rated torque at zero speed. The element to be tested can be loaded at standstill to determine the starting torque.

Optical Speed Sensor

Each PB Series Dynamometer has a standard optical speed sensor. PB 43 has an optical speed sensor with a 30 PPR (Pulses Per Revolution); PB 65, PB 115 & PB 15 has an optical speed sensor with a 60 PPR. For higher speed resolution in low speed applications, Magtrol offers a 600 PPR or 6 000 PPR encoder as an option.

[post_title] => PB Series - Powder Brake Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => powder-brake-dynamometers-pb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-03-31 22:55:34

[post_modified_gmt] => 2025-03-31 17:25:34

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=512

[menu_order] => 46

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). WB Series Dynamometers integrate a torque measuring system with accuracy ratings of ± 0.3 % to ± 0.5 % full scale, depending on size and system configuration.

Features

- 12 Models with Maximum Torque from 400 mN·m to 560 N·m (56.6 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed (≤ 80 000)

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 80 000 rpm (up to 100 000 rpm with

WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer is equipped with an optical speed sensor.

WB 32 is equipped with a 4 PPR (Pulses Per Revolution) encoder, WB 43 and WB 65 HS are equipped with a 30 PPR encoder; WB 65, WB 115 & WB 15 are equipped with a 60 PPR encoder.

[post_title] => WB Series - Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => eddy-current-dynamometers-wb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-07-01 01:12:12

[post_modified_gmt] => 2025-06-30 19:42:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=507

[menu_order] => 45

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 8320

[post_author] => 2

[post_date] => 2020-04-03 18:16:51

[post_date_gmt] => 2020-04-03 12:46:51

[post_content] => Magtrol’s WB 23 and WB 27 Eddy-Current Dynamometers are designed for very high-speed motors and dental or surgical tool testing applications. By providing a braking torque that is proportional to the rotational speed, rated torque is reached at the rated speed. The Dynamometer features a low level of inertia, due to small rotor dimensions, and brake cooling is provided by air flow inside the dynamometer housing.

A PT temperature sensor continuously monitors the brake temperature and alarms the DSP 7010 Controller to stop the brake excitation current in order to protect the dynamometer from overheating. Torque is measured by a reaction torque transducer placed on the stator. The dynamometer has a torque measuring accuracy rating of ± 0.2 % full scale. The speed is measured by an optical sensor and a 2-PPR encoder. This sensor measures speeds between 10 000 rpm and 100 000 rpm with a full scale accuracy of ± 0.06 % (using a DSP 7010).

Features

- Torque: 80 mN·m and 150 mN·m

- Speed: up to 100 000 rpm

- Power: 250 W continuous; up to 500 W (WB 23) or 1 kW (WB 27) intermittent

- Low inertia

- Very low residual torque

- Stable and smooth braking torque

- Measuring system with air-bearing

- Data acquisition via DSP 7010 Controller and M-TEST Software

- Built-in electronics with Torque & Speed measurement

Operating Principles

The WB 23 and WB 27 Eddy-current Dynamometer provides full braking power at high speed. This type of brake has been specially designed to test motors rotating at speeds up to 100 000 rpm, with the braking torque dependent upon the rotation speed. Due to the 2-PPR encoder, the system is not designed to provide closed loop control below 10 000 rpm.

The dynamometer includes air bearings for minimizing friction and assuring the best possible torque reading accuracy. It is necessary to connect the air input through the air filtering and drying kit (included).

[post_title] => WB 23 and WB 27 - High-Speed Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => wb-23-and-wb-27-high-speed-eddy-current-dynamometers

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-13 00:09:44

[post_modified_gmt] => 2024-02-12 18:39:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/india/?post_type=product&p=8320

[menu_order] => 43

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 5

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 410

[post_author] => 1

[post_date] => 2017-04-05 12:20:44

[post_date_gmt] => 2017-04-05 12:20:44

[post_content] => Hysteresis Brake Dynamometers (HD Series) are versatile and ideal for testing in the low to medium power range (maximum 14 kW intermittent duty). With a Hysteresis Braking system, the Dynamometers do not require speed to create torque, and therefore can provide a full motor ramp from free-run to locked rotor. Brake cooling is provided by convection (no external source), by compressed air or by dedicated blower, depending on the model. All Magtrol Hysteresis Dynamometers have accuracy ratings of ± 0.25% full scale — depending on size and system configuration.

Features

- 16 Standard Models with Maximum Torque from 2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

- Hysteresis Braking System: Provides precise torque loading independent of shaft speed

- Motor Testing from No Load to Locked Rotor

- Accuracy: ±0.25% (Full Scale)

- Air Flow Sensor: For protection against overheating and operator error

- Standard Torque Units: English, Metric and SI

- Custom Dynamometers: for special torque and speed requirements

- Easy Calibration

The Hysteresis Braking System

All Magtrol Hysteresis Dynamometers absorb power with a unique Hysteresis Braking System which provides frictionless torque loading independent of shaft speed. The Hysteresis Brake provides torque by the use of two basic components - a reticulated pole structure and a specialty steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from the field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 36639f41cc1d5d7a4022870be9868641

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

The WB32 dynamometer can be integrated as a component of a measurement system.

The WB32 dynamometer can be integrated as a component of a measurement system. [post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 515

[post_author] => 1

[post_date] => 2017-04-05 13:48:34

[post_date_gmt] => 2017-04-05 13:48:34

[post_content] => Finally… a Micro Dyne system designed specifically for your micro motors!

With over 50 years’ experience in dynamometer design and torque measurement, Magtrol has revolutionized the industry. Magtrol’s new Micro Dyne, capable of measuring extremely low torques (2.0 mN·m can be resolved to 0.0004 mN·m), is designed exclusively for testing miniature and micro motors.

For the utmost convenience, the Micro Dyne is packaged as a complete motor testing system. Everything that is needed to accurately and efficiently test miniature motors and micro motors is included with the purchase of a Magtrol Micro Dyne. The only component that needs to be supplied by the customer is a laptop or desktop personal computer and a motor power supply.

[post_title] => Micro Dyne System

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => micro-dyne-system

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:45:58

[post_modified_gmt] => 2023-04-21 15:15:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=515

[menu_order] => 42

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => The Powder Brake Dynamometer (PB Series) contains, as its name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction. They are ideal for applications operating in the low to middle speed range or when operating in the middle to high torque range. Like

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 515

[post_author] => 1

[post_date] => 2017-04-05 13:48:34

[post_date_gmt] => 2017-04-05 13:48:34

[post_content] => Finally… a Micro Dyne system designed specifically for your micro motors!

With over 50 years’ experience in dynamometer design and torque measurement, Magtrol has revolutionized the industry. Magtrol’s new Micro Dyne, capable of measuring extremely low torques (2.0 mN·m can be resolved to 0.0004 mN·m), is designed exclusively for testing miniature and micro motors.

For the utmost convenience, the Micro Dyne is packaged as a complete motor testing system. Everything that is needed to accurately and efficiently test miniature motors and micro motors is included with the purchase of a Magtrol Micro Dyne. The only component that needs to be supplied by the customer is a laptop or desktop personal computer and a motor power supply.

[post_title] => Micro Dyne System

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => micro-dyne-system

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:45:58

[post_modified_gmt] => 2023-04-21 15:15:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=515

[menu_order] => 42

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 512

[post_author] => 1

[post_date] => 2017-04-05 13:31:33

[post_date_gmt] => 2017-04-05 13:31:33

[post_content] => The Powder Brake Dynamometer (PB Series) contains, as its name suggests, a magnetic powder. The electrical current passing through the coil generates a magnetic field, which changes the property of the powder, thus producing a smooth braking torque through friction. They are ideal for applications operating in the low to middle speed range or when operating in the middle to high torque range. Like