Product Description

Magtrol’s DSP 7010 Series – Dynamometer Controller employs advanced Digital Signal Processing technology to provide superior motor testing capabilities. Designed for use with any Magtrol Hysteresis, Eddy-Current or Powder Dynamometer, Magtrol In-Line Torque Transducer or auxiliary instrumentation, the DSP 7010 can provide complete PC control via the USB or GPIB interface. With up to 488 readings per second, the DSP 7010 is ideally suited for both the test lab and the production line.

Features

- DSP7011 Single Channel: Cost-effective & User-friendly

- DSP7012 Dual Channel: Versatile with complete functionality; allows two fully independent configurations

- Speed & Torque Operating Modes: Provides independent PID settings for improved Dynamometer control

- Built-In Alarm System: power, speed, torque, temperature, air flow, water flow, electrical overload and external inputs

- Can be used independently or, ideally, in combination with Magtrol software to meet all requirements of motor testing

- High Speed Data Acquisition: ≤ 488 samplings / second (torque, speed, time, angle, etc.)

- Fast Full-Curve Data Acquisition: Free-run to locked rotor in seconds

- Programmable Digital PID Values: Controlled and stored via M-TEST Software or controlled manually

- Built-in Current-Regulated Supply: ≤ 1A

- Selectable Torque Units: Imperial, Metric and SI

- Digital Filter for Torque Signals

- PC Connection: USB & GPIB (IEEE-488.2)

- Position Measurement: two quadrature decoders

- Built-in I/O card accessible with software

- Operation via frontpanel keyboard computer

- High Quality, Easy-to-Read Vacuum Fluorescent Readout

- Desktop Housing or Rack Mounting (19″ / 2U)

- Command Compatible: compatible with the DSP 7000

Specifications

| MEASUREMENT CHARACTERISTICS |

| Maximum Torque |

99 999 units |

| Maximum Speed |

199 999 RPM |

| Torque Accuracy |

2 V range ±0.01 % of range (±0.2 mV) (used on all HD Series other than HD 5 Series)

10 V range ±0.01% of range (±1 mV) (used on all except HD Series) |

| Speed Accuracy |

0.01 % of reading from 5 ... 199 999 rpm |

| ELECTRICAL CHARACTERISTICS |

| Voltage Requirements

|

85-264 VAC 50/60 Hz |

| Power Requirements |

210 VA |

| Fuses (5 × 20 mm) |

IEC T 2.5 A 250 V L

|

| Max. Compliance Voltage |

48 V DC, Brake Output |

| Max. Brake Output Current |

1 Amp, Calibrated that 100% open loop = 1 Amp |

| TSC Power Supplies |

Torque Sensor: 24 V DC, max. 200 mA (power supply fault protected)

Encoder: 5 V DC, max. 200 mA (internal fuse at 500 mA) |

| ENVIRONMENT |

| Operating Temperature |

5 ºC ... 40 ºC |

| Relative Humidity |

< 80% |

| Temperature Coefficient |

0.004% of range/°C of 5 V DC for both channels |

| Altitude |

max. 2 000 m |

Applications

In the laboratory, the DSP7010’s high sample rate provides superior resolution for data acquisition and curve plotting. This allows capturing more usable motor test data during switching, breakdown and other transitional areas of the motor test curve. For production and incoming inspection, the DSP7010 displays torque, speed and power at all times, allowing the Controller to be used as a manual stand-alone unit or as part of a complete PC system.

WP_Query Object

(

[query] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 507

[1] => 410

[2] => 866

[3] => 899

)

[post__not_in] => Array

(

[0] => 9308

)

)

[query_vars] => Array

(

[post_type] => product

[ignore_sticky_posts] => 1

[no_found_rows] => 1

[posts_per_page] => -1

[orderby] => rand

[post__in] => Array

(

[0] => 507

[1] => 410

[2] => 866

[3] => 899

)

[post__not_in] => Array

(

[0] => 9308

)

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[static] =>

[pagename] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

)

[category__and] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[suppress_filters] =>

[cache_results] =>

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[nopaging] => 1

[comments_per_page] => 50

[order] =>

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

)

[relation] => AND

[table_aliases:protected] => Array

(

)

[queried_terms] => Array

(

)

[primary_table] => wp_10_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[request] => SELECT wp_10_posts.* FROM wp_10_posts WHERE 1=1 AND wp_10_posts.ID IN (507,410,866,899) AND wp_10_posts.post_type = 'product' AND (wp_10_posts.post_status = 'publish') ORDER BY RAND()

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 899

[post_author] => 1

[post_date] => 2017-04-06 17:52:48

[post_date_gmt] => 2017-04-06 17:52:48

[post_content] => If currents continuously reach above 20 amps, an external sensor must be used. Magtrol offers three different types of external shunts for use with Magtrol Power Analyzers. The HA Series shunt, designed for power cable hook-up utilizing 3/8-16 screws, has an insulating base and can be mounted on conductive surfaces. The LAB Series shunt also comes with an insulating base, along with thumb screws for the power leads and knurled nuts on the sensing terminals. The FL Series is a relatively small bus, bar-mounted shunt with large end blocks. The comparatively large end blocks and short spacing aid in cooling and allow the shunt to operate in more extreme environments. All shunts are calibrated on equipment with current certifications traceable to N.I.S.T.

[post_title] => External Shunts

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => external-shunts

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 21:00:52

[post_modified_gmt] => 2023-04-21 15:30:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=899

[menu_order] => 112

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 866

[post_author] => 1

[post_date] => 2017-04-06 16:51:38

[post_date_gmt] => 2017-04-06 16:51:38

[post_content] => PT Series T-slot Base Plates are used for creating a basic test rig by mounting a Magtrol Dynamometer and/or Torque Transducer in line with the unit to be tested. Its solid, warp-resistant structure and multiple, single-sided T-slots enable modular construction that is cost-effective and easy to assemble.

[post_title] => PT Series - T-Slot Base Plates

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => pt-series-t-slot-base-plates

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 20:55:37

[post_modified_gmt] => 2023-04-21 15:25:37

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=866

[menu_order] => 62

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 507

[post_author] => 1

[post_date] => 2017-04-05 13:21:38

[post_date_gmt] => 2017-04-05 13:21:38

[post_content] => Eddy-Current Brake Dynamometers (WB Series) are ideal for applications requiring high speeds and also when operating in the middle to high power range. Eddy-Current Brakes provide increasing torque as the speed increases, reaching peak torque at rated speed. The dynamometers have low inertia as a result of small rotor diameter. Brake cooling is provided by a water circulation system, which passes inside the stator to dissipate heat generated by the braking power, providing high continuous power ratings (max. 140 kW). WB Series Dynamometers integrate a torque measuring system with accuracy ratings of ± 0.3 % to ± 0.5 % full scale, depending on size and system configuration.

Features

- 12 Models with Maximum Torque from 400 mN·m to 560 N·m (56.6 oz·in to 413 lb·ft)

- Braking Power: from 500 W to 140 kW

- Stable Braking Torque, without Shock

- Low Moment of Inertia

- Low Residual Torque

- Operating Direction CW / CCW

- Braking Torque Measurement Integrated

- High Rotational Speed (≤ 80 000)

- Integrated Optical Speed Sensor

- Special designs available upon request

Operating Principles

The WB Eddy-Current Dynamometers develop their full power at high rotation speeds. The WB Series is particularly intended for motors which rotate at high speeds, up to 80 000 rpm (up to 100 000 rpm with

WB 23 / 27; see specific datasheet). The braking torque depends on the rotation speed.

Optical Speed Sensor

Each WB Series Dynamometer is equipped with an optical speed sensor.

WB 32 is equipped with a 4 PPR (Pulses Per Revolution) encoder, WB 43 and WB 65 HS are equipped with a 30 PPR encoder; WB 65, WB 115 & WB 15 are equipped with a 60 PPR encoder.

[post_title] => WB Series - Eddy-Current Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => eddy-current-dynamometers-wb-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-07-01 01:12:12

[post_modified_gmt] => 2025-06-30 19:42:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=507

[menu_order] => 45

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 410

[post_author] => 1

[post_date] => 2017-04-05 12:20:44

[post_date_gmt] => 2017-04-05 12:20:44

[post_content] => Hysteresis Brake Dynamometers (HD Series) are versatile and ideal for testing in the low to medium power range (maximum 14 kW intermittent duty). With a Hysteresis Braking system, the Dynamometers do not require speed to create torque, and therefore can provide a full motor ramp from free-run to locked rotor. Brake cooling is provided by convection (no external source), by compressed air or by dedicated blower, depending on the model. All Magtrol Hysteresis Dynamometers have accuracy ratings of ± 0.25% full scale — depending on size and system configuration.

Features

- 16 Standard Models with Maximum Torque from 2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

- Hysteresis Braking System: Provides precise torque loading independent of shaft speed

- Motor Testing from No Load to Locked Rotor

- Accuracy: ±0.25% (Full Scale)

- Air Flow Sensor: For protection against overheating and operator error

- Standard Torque Units: English, Metric and SI

- Custom Dynamometers: for special torque and speed requirements

- Easy Calibration

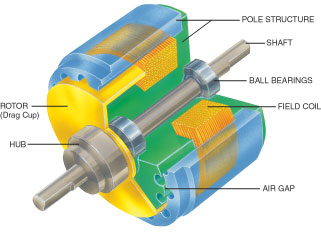

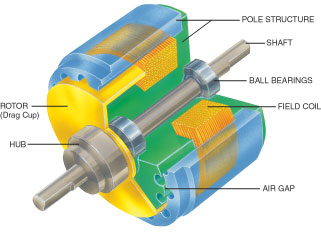

The Hysteresis Braking System

All Magtrol Hysteresis Dynamometers absorb power with a unique Hysteresis Braking System which provides frictionless torque loading independent of shaft speed. The Hysteresis Brake provides torque by the use of two basic components - a reticulated pole structure and a specialty steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from the field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 899

[post_author] => 1

[post_date] => 2017-04-06 17:52:48

[post_date_gmt] => 2017-04-06 17:52:48

[post_content] => If currents continuously reach above 20 amps, an external sensor must be used. Magtrol offers three different types of external shunts for use with Magtrol Power Analyzers. The HA Series shunt, designed for power cable hook-up utilizing 3/8-16 screws, has an insulating base and can be mounted on conductive surfaces. The LAB Series shunt also comes with an insulating base, along with thumb screws for the power leads and knurled nuts on the sensing terminals. The FL Series is a relatively small bus, bar-mounted shunt with large end blocks. The comparatively large end blocks and short spacing aid in cooling and allow the shunt to operate in more extreme environments. All shunts are calibrated on equipment with current certifications traceable to N.I.S.T.

[post_title] => External Shunts

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => external-shunts

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 21:00:52

[post_modified_gmt] => 2023-04-21 15:30:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=899

[menu_order] => 112

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4b9e9eb0391746edd8e40976ec6b2b11

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 899

[post_author] => 1

[post_date] => 2017-04-06 17:52:48

[post_date_gmt] => 2017-04-06 17:52:48

[post_content] => If currents continuously reach above 20 amps, an external sensor must be used. Magtrol offers three different types of external shunts for use with Magtrol Power Analyzers. The HA Series shunt, designed for power cable hook-up utilizing 3/8-16 screws, has an insulating base and can be mounted on conductive surfaces. The LAB Series shunt also comes with an insulating base, along with thumb screws for the power leads and knurled nuts on the sensing terminals. The FL Series is a relatively small bus, bar-mounted shunt with large end blocks. The comparatively large end blocks and short spacing aid in cooling and allow the shunt to operate in more extreme environments. All shunts are calibrated on equipment with current certifications traceable to N.I.S.T.

[post_title] => External Shunts

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => external-shunts

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 21:00:52

[post_modified_gmt] => 2023-04-21 15:30:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=899

[menu_order] => 112

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4b9e9eb0391746edd8e40976ec6b2b11

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

[post_title] => HD Series - Hysteresis Dynamometers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => hysteresis-dynamometers-hd-series

[to_ping] =>

[pinged] =>

[post_modified] => 2025-06-05 21:16:35

[post_modified_gmt] => 2025-06-05 15:46:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=410

[menu_order] => 41

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 4

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 899

[post_author] => 1

[post_date] => 2017-04-06 17:52:48

[post_date_gmt] => 2017-04-06 17:52:48

[post_content] => If currents continuously reach above 20 amps, an external sensor must be used. Magtrol offers three different types of external shunts for use with Magtrol Power Analyzers. The HA Series shunt, designed for power cable hook-up utilizing 3/8-16 screws, has an insulating base and can be mounted on conductive surfaces. The LAB Series shunt also comes with an insulating base, along with thumb screws for the power leads and knurled nuts on the sensing terminals. The FL Series is a relatively small bus, bar-mounted shunt with large end blocks. The comparatively large end blocks and short spacing aid in cooling and allow the shunt to operate in more extreme environments. All shunts are calibrated on equipment with current certifications traceable to N.I.S.T.

[post_title] => External Shunts

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => closed

[post_password] =>

[post_name] => external-shunts

[to_ping] =>

[pinged] =>

[post_modified] => 2023-04-21 21:00:52

[post_modified_gmt] => 2023-04-21 15:30:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.magtrol.com/?post_type=product&p=899

[menu_order] => 112

[post_type] => product

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 0

[max_num_pages] => 0

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] => 1

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_posts_page] =>

[is_post_type_archive] => 1

[query_vars_hash:WP_Query:private] => 4b9e9eb0391746edd8e40976ec6b2b11

[query_vars_changed:WP_Query:private] =>

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)